Blog

How to Find a Reliable Hotel Furniture Supplier

Table of Contents

Two months before opening, everything looked on track — until the wardrobes arrived. Half didn’t match the site drawings. The “manufacturer” had outsourced production, and every batch came out different. The general contractor paid storage fees, the owner lost revenue, and one weak supplier decision cost weeks of delay and thousands of dollars.

If you’ve ever managed a hotel project, you know that sinking feeling when a small factory mistake turns into a major crisis. It’s not just furniture — it’s your timeline and reputation.

This guide helps developers, interior designers, and procurement managers find a trusted hotel furniture supplier — based on lessons learned from real 5-star hospitality projects in Asia, Europe, America, Australia and all aorund the world.

Step 1: Identify the Real Project Risks — Not Just the Furniture List

Many developers think they’re buying furniture. In reality, they’re buying risk control. Every wardrobe, vanity, or sofa depends on precise tolerances, material specs, and site coordination.

Studies show that 70 % of project delays stem from mismatches between design drawings and production accuracy. A 1 mm error can ruin an entire joinery alignment.

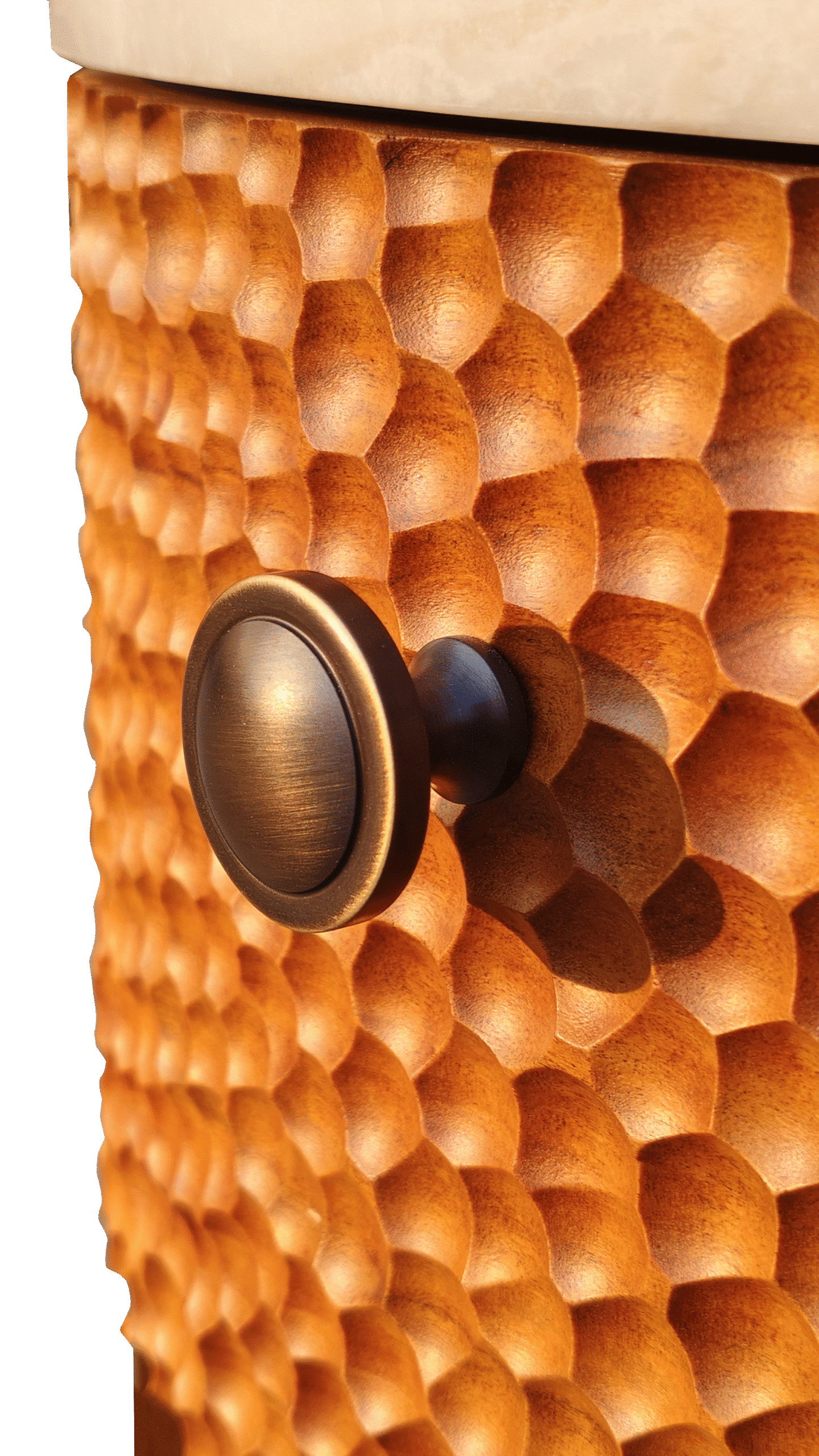

Factories that control their own CNC + joinery workshops can hold precision within ±0.5 mm. This ensures smoother installation and predictable results.

By contrast, suppliers who outsource work to small subcontractors introduce inconsistency.

👉 Always ask: “Do you produce in-house, or do you subcontract?”

The answer determines how much control they have over your schedule.

Step 2: Vet the Supplier’s Subcontract Network

Not every hotel furniture manufacturer in China is a real factory. Many online “suppliers” are trading companies forwarding your drawings to random workshops. Every layer adds delay and risk.

A legitimate hospitality furniture supplier proudly shows proof of production — clear workshop breakdowns (veneer, upholstery, metal, lighting), machinery lists, and live factory videos.

Ask for:

Geotagged factory photos showing workers and signage

Video calls from veneer, upholstery, or metal workshops

Production licenses and certifications

Integrated manufacturers like Betherev handle FF&E + lighting under one roof — eliminating subcontracting chaos, ensuring one quality system, and keeping coordination seamless across all departments.

Step 3: Evaluate Design Translation — Not Just the Quotation

Most project overruns come from poor design interpretation, not price. High-end designers specify detailed finishes, veneer directions, and edge profiles that low-cost factories misread.

A capable custom hotel furniture supplier should have a bilingual engineering team to create:

Shop drawings and exploded diagrams

Material boards with texture and color references

Finish samples before quoting

Test them with one prototype — for example, a Marriott-standard bedside table. Evaluate veneer matching, edge detailing, and labeling accuracy.

If a sample meets your expectations, you can trust their consistency across hundreds of units.

Delays often appear only at installation — when the furniture doesn’t match approvals. By then, rework costs explode.

A professional hotel furniture manufacturer makes QC measurable:

Digital tracking with photos at 30 / 60 / 90 % progress

Burn-in tests for lighting units

Detailed QC reports

Technical standards to demand:

ΔE ≤ 1.0 color variance across rooms

E0 plywood certificates (low formaldehyde)

CRIB 5 foam for fire safety

Ask for QC samples and test reports before shipment, not after packing. It’s the simplest way to ensure that what arrives matches your approval.

Step 5: Optimize Logistics Before Production

Inefficient packing wastes thousands in freight. One cubic meter of unused container space can cost $150 – $200.

Good hospitality furniture suppliers design packaging for maximum CBM utilization. Flat-pack, knock-down, or shared crates reduce wasted space by 10 – 15 %.

Before production, request:

CBM optimization drawings

Packaging test reports

40HQ loading plans and protection details

Smart packaging = lower breakage risk + faster installation. When logistics is part of design, your handover stays on schedule.

Step 6: Build a Long-Term Procurement Relationship

Frequent supplier changes create inconsistency across properties. Every new factory starts from zero — retesting materials and reapproving samples. That wastes time and budget.

Long-term partnerships cut approval time by up to 40 %. Factories like Betherev maintain client archives — veneer formulas, hardware specs, mold libraries — ensuring identical finishes when you expand your brand to new cities.

Treat sourcing as vendor development, not one-off purchasing. The goal is a repeatable, predictable supply chain that delivers the same five-star quality every time.

Conclusion — Turn FF&E Procurement into Predictable ROI

Most hotel project delays come from four causes: outsourced production, unclear drawings, weak QC, and poor logistics.

Partner with a factory-direct supplier that controls joinery, loose furniture, and lighting under one roof to reduce those risks by up to 30 %.

Betherev / Classic Tongda has over 30 years of experience as a China-based hotel furniture supplier serving brands like Marriott, Hilton, and Accor. Our integrated FF&E solutions help you save time, budget, and headaches — from design translation to container loading.

📞 Get Your Free Project Audit + CBM Optimization Plan → [Contact Us]

FAQs

Start by confirming that the supplier owns its own production workshops — joinery, veneer, upholstery, metal, and lighting.

Ask for geotagged factory photos or live videos to prove in-house production.

A real China hotel furniture supplier should also show past 5-star project references and third-party certifications such as ISO 9001 or E0 plywood certificates.

A true hotel furniture manufacturer in China controls production, QC, and packaging inside its facility.

Trading companies act as middlemen, forwarding drawings to small subcontractors — which often causes delays, quality issues, and miscommunication.

Choosing a factory-direct hospitality furniture supplier ensures consistent quality and faster delivery.

Every hotel project has unique room layouts, materials, and branding.

A custom hotel furniture supplier can tailor dimensions, veneers, and finishes to match the designer’s intent, avoiding costly rework on-site.

This flexibility also improves installation efficiency and overall design harmony.

Request a sample piece or mock-up room before full production.

Inspect tolerance accuracy (± 0.5 mm), veneer matching, and hardware durability.

Ask for QC photos at 30 / 60 / 90 % progress, plus reports showing ΔE ≤ 1.0 color variance and CRIB 5 foam compliance for upholstery.

For mid- to large-scale projects, the typical lead time is 60 – 90 days after design approval, depending on volume and material availability.

Well-organized hotel furniture suppliers plan logistics early with CBM optimization to ensure on-time handover.

Working with the same supplier across multiple projects creates a consistent material database — same colors, veneers, and hardware.

This continuity cuts sample approval time by up to 40 % and keeps brand finishes identical across different properties.

Factories like Betherev maintain archives of all client materials and finishes for future expansions or refurbishments.

Comprehensive hospitality furniture suppliers usually provide:

Guest-room casegoods (beds, wardrobes, desks)

Loose furniture (chairs, sofas, coffee tables)

Public-area joinery and reception counters

Outdoor and pool furniture

Custom lighting fixtures integrated into FF&E

Simply share your FF&E drawings or BOQ for a free project audit.

Our engineering team will prepare shop drawings, CBM calculations, and quotation details within a few days.

We also offer mock-up production, packaging tests, and QC documentation before mass order confirmation.

📩 Contact Betherev → [Request a Quotation]