Blog

How to Choose the Right Hotel Bed Supplier

(2025 Guide for Developers & Procurement Teams)

Table of Contents

A hotel bed does more than hold a mattress—it decides whether your guests wake up refreshed or ready to complain at the front desk. And the hotel bed supplier you choose can determine your maintenance cost, review scores, and replacement cycle for years.

Whether you’re building a new hotel, refreshing rooms, or standardizing across multiple properties, choosing the right hotel bed supplier is one of the highest-impact decisions you’ll make. This guide breaks everything down clearly so you can pick a partner with confidence.

What Makes a Hotel Bed Supplier Truly Reliable?

A reliable hotel bed supplier is someone who consistently delivers the same quality you saw in the sample room—no surprises, no excuses. One of the first signs of a good supplier is actual experience producing the full package: bedheads, upholstered beds, feature walls, and bed bases. When a factory understands how all these pieces fit together, you’ll get cleaner alignment, fewer installation problems, and a room that looks exactly like the design intent.

In-house joinery and upholstery teams make a huge difference too. When everything is done under one roof, you avoid the common problems that come from outsourcing—different craftsmanship standards, mismatched materials, and delayed communication. A supplier who controls its own carpentry, metalwork, and upholstery can maintain consistent quality from start to finish.

Certifications also matter, especially for hotels. ISO certifications confirm the factory has proper systems, and fire-rating compliance proves the materials are safe for hospitality environments. A strong hospitality portfolio shows the supplier has worked with the pressure, timelines, and quality requirements of real hotel projects—not just residential jobs.

Lead time reliability is another big test. A dependable hotel bed supplier can produce for 50, 200, or even 500 rooms without delays. They understand batching, logistics, and how to scale production without sacrificing quality. When lead times are stable, the entire FF&E timeline becomes smoother for your design, construction, and opening schedule.

There are also a few red flags that should make you pause. Inconsistent samples, weak documentation, missing test reports, or no detailed shop drawings are warning signs that the supplier may not have proper systems in place. If they can’t get the first room right, the full project will struggle even more.

Evaluating Bed Quality: Bedhead, Bed Base & Total Bed Construction

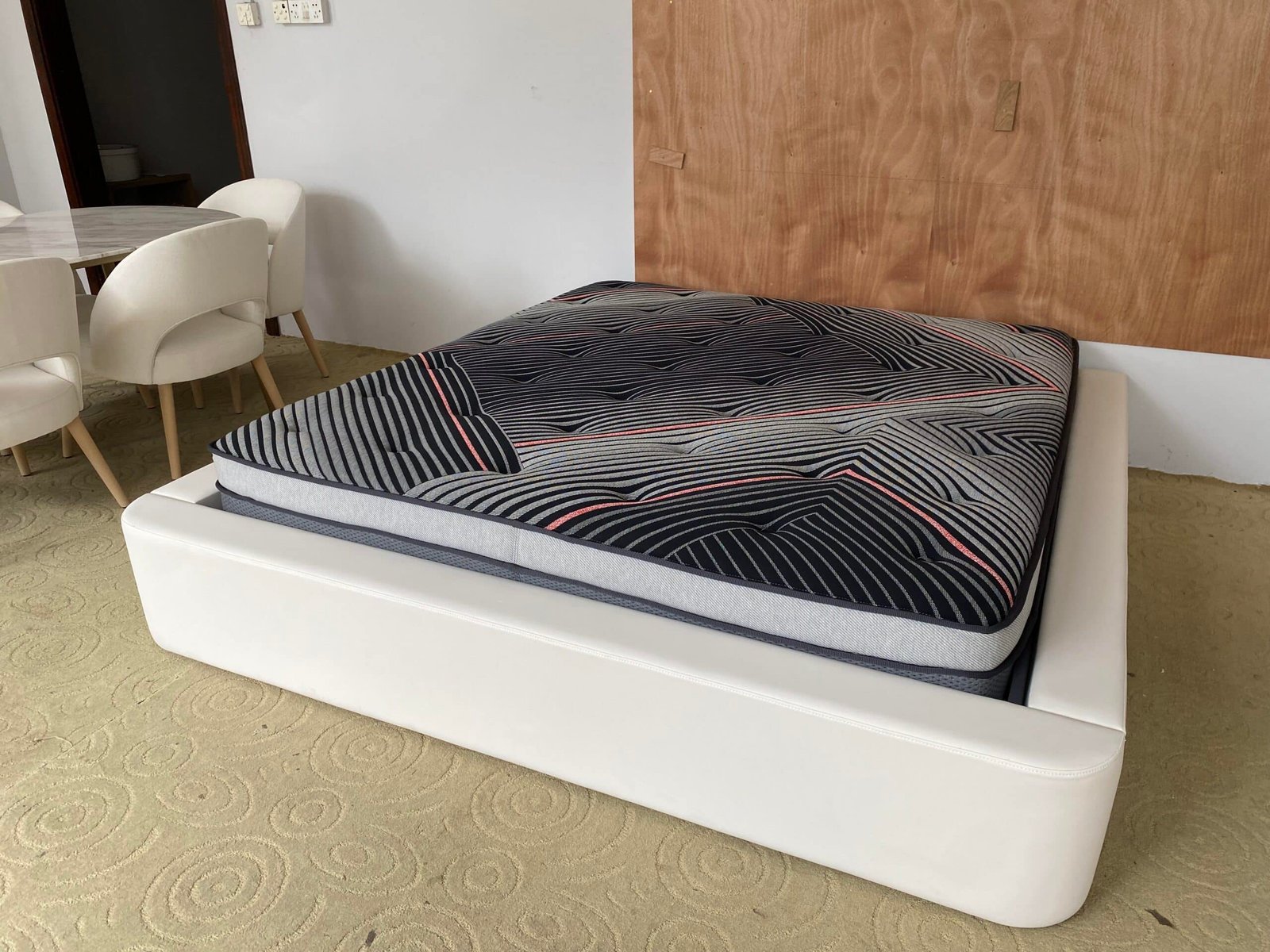

When you’re choosing beds for a hotel, it helps to look at the whole construction rather than judging pieces in isolation. A good hotel bed isn’t just comfortable—it needs to survive years of guests, cleaners, trolleys, and constant movement. That’s why the bedhead, bed base, and even the background wall all matter more than most people expect.

A strong bedhead starts with a solid frame. Look for plywood or hardwood frames because they hold their shape and don’t warp when humidity changes. The foam inside should feel supportive, not spongy—higher-density foam keeps its shape longer. And if the bedhead is upholstered, check the fabric’s rub count. You want commercial-grade fabric (usually 35,000–50,000 Martindale) so it can handle suitcases, backpacks, and daily cleaning. Many hotels today also prefer stainless steel bedhead hanging systems because they offer stronger support, cleaner alignment, and easier installation compared to traditional wooden cleats.

The bed base is where most of the stress goes, so construction matters a lot. Metal bases are strong and long-lasting, timber bases feel warmer and quieter, and hybrid bases give you the best of both. Whatever the material, a good bed base should have an anti-squeak design—tiny felt pads or rubber buffers make a big difference. Load capacity is another big one. Hotel beds should be built to handle far more weight than residential ones.

For hotels that use a feature wall or bed background, durability becomes even more important. These panels take a lot of impact from pillows, luggage, and cleaning tools. Choose materials with moisture resistance—plywood or HMR (high-moisture-resistant) panels work well. Pay attention to how the panels are fixed to the wall, too; secure mounting prevents long-term rattling. Metal trims or sealed edges will protect the corners from chipping.

One thing you should always avoid in humid climates is MDF. It swells, softens, and loses strength when exposed to moisture, even small amounts in the air. Once it swells, it never goes back to its original size, which leads to cracks in upholstery, loose panels, and shorter lifespan. For tropical or coastal hotels, MDF almost always becomes a maintenance problem.

Finally, don’t forget certifications. CAL117 and BS7177 help ensure your foam and upholstery meet fire-safety standards. Structural load tests confirm the bed base won’t fail under heavy use. These tests aren’t just paperwork—they protect your hotel from accidents and expensive replacements.

Pricing, Budgeting & Total Cost of Ownership from a Hotel Bed Supplier

When you’re comparing prices for hotel beds, it’s important to make sure every quote is based on the exact same specs. Two bedheads might look identical in photos, but one could be plywood with commercial upholstery while the other is MDF with thin foam. The same goes for bed bases and background walls — you need matching materials, matching dimensions, and matching hardware before the numbers mean anything. Otherwise, you’re comparing apples to cardboard.

A lot of the real costs hide inside the structure. Weak slats can sag after a few months, leading to guest complaints and costly replacements. Cheap fabrics pill quickly, so the bed looks old even when it’s new. Soft timber frames warp or crack when housekeeping moves beds for cleaning. And if the wall mounting for the bedhead is poorly designed, the whole panel can loosen or start banging every time someone sits down. These issues never show up in the quotation — they show up in your maintenance budget later.

Packaging and transport matter more than most people expect. A well-built bed can still arrive damaged if the factory uses thin cartons, no corner protectors, or poor palletizing. Long-distance shipping is rough, especially for bulky pieces like bed bases and feature walls. Proper foam wrapping, honeycomb boards, and solid wooden crates help prevent dents, tears, and chipped edges. Good packaging doesn’t just protect the furniture — it protects your project timeline.

Spending more on a solid bed base almost always pays off. A strong base keeps the mattress stable, reduces noise, and handles heavy use without loosening. It also reduces the need for annual repairs or constant retightening. When the base is done right — metal connectors, solid internal bracing, high-density slats — it becomes a long-term asset instead of a recurring expense.

One hotel learned this the hard way. After receiving a batch of bedheads with simple MDF frames and weak back supports, they faced constant repairs every quarter. Eventually, they upgraded to a reinforced plywood structure with proper wall cleats. Maintenance complaints dropped immediately, and their annual repair spending fell by more than half. A slightly higher upfront cost turned into years of savings and fewer headaches for the engineering team.

Design, Ergonomics & Guest Experience

A well-designed bedhead does more than look pretty—it actually shapes how guests use the room. The height, angle, and padding all matter. A bedhead that’s slightly tilted back with firm padding makes it comfortable for guests to sit up and read, eat, or work on a laptop without feeling like they’re leaning on a brick. You want it high enough to frame the pillows nicely, but not so tall that it overwhelms the room.

The height of the bed base plays a big role in both accessibility and housekeeping speed. A slightly higher bed makes it easier for housekeeping to tuck in linens without bending too low, which reduces fatigue over hundreds of rooms. For guests, especially older travellers, a proper bed height makes it easier to sit down and stand up safely. It’s one of those small details that quietly improves comfort.

Feature-wall design behind the bed does a lot of heavy lifting visually. It helps define the room’s identity and gives the space a “finished” feeling even before any loose furniture is added. Whether it’s timber veneer, fabric panels, or a simple painted accent, the feature wall anchors the bed and adds depth to the room without taking up extra space.

When you’re choosing fabrics for upholstered bedheads, stain-resistant and easy-clean materials are a must. Guests bring makeup, hair products, food, and sometimes even luggage that rubs against the headboard. A durable, commercial-grade fabric helps the bedhead stay clean and fresh-looking longer, which reduces replacement frequency.

Noise control is another quiet hero of guest satisfaction. Anti-squeak joints, simple wall bumpers behind the bed, and felt pads at contact points stop the bed from rattling every time someone moves. These tiny additions make the whole room feel more solid and premium—and they prevent noise complaints from light sleepers in the next room.

Working With a Supplier: Drawings, Samples, Production & QC

Working with a hotel bed supplier is a lot smoother when everyone’s speaking the same visual language. That’s where shop drawings come in. These drawings show the exact bedhead height, bed base structure, wall panel layout, and every little detail that affects how the pieces fit together in the room. When the drawings are clear, you avoid those “surprise” measurements that cause delays on site.

Before anything gets built, you’ll go through a round of sample approvals. This usually includes the fabric for the upholstered bedhead, the timber veneer tone, and even small things like the stitch lines. These small details matter more than most people think. A slightly different veneer color can throw off an entire room, and an uncomfortable stitch line can irritate guests.

For larger projects, most hotels require a mock-up room before mass production. This is basically a full test room with the final bedhead, bed base, and wall panels installed exactly as they will be in the real hotel. It’s your chance to catch design issues, tweak materials, or adjust proportions. Fixing a mistake here costs almost nothing compared to discovering it after 200 rooms are already made.

Once production starts, factory QC becomes the backbone of quality. A good supplier checks alignment on the bedhead panels, ensures the joinery is tight, confirms the slat spacing on the bed base is strong enough, and makes sure wall panels are properly reinforced for fixing. You want consistency across every unit, not just the sample.

The last step is packaging and installation guidelines. Strong packaging prevents scratches, corner damage, and crushed upholstery during transport. Clear installation instructions help contractors mount bedheads and wall panels safely and at the right height. Good packaging protects your furniture during the journey. Good instructions protect your schedule during installation.

Conclusion

Choosing a hotel bed supplier isn’t just a purchasing task—it’s a long-term investment in guest comfort, brand consistency, and operational efficiency. When you evaluate materials, customization options, durability, and supplier track record, you dramatically reduce headaches later.

If you’re planning a new hotel, renovating rooms, or seeking a long-term partner, now’s the perfect time to shortlist suppliers who can meet your performance, design, and budget goals.

FAQs

Look for a supplier with proven hospitality experience, in-house joinery and upholstery, ISO certifications, fire-rating compliance, and the ability to produce consistent quality across 50–500 rooms. A portfolio of completed hotel projects is a strong indicator of reliability.

Hotel beds use stronger frames, commercial-grade fabrics, high-density foam, and durable hardware. They’re engineered for heavy use, frequent housekeeping, and higher weight loads compared to residential beds.

Plywood or hardwood frames, high-density foam, and commercial-grade upholstery are best for bedheads. For bed bases, metal, solid timber, or hybrid structures with anti-squeak design provide the best durability.

Stainless steel bedhead hanging systems offer stronger support, cleaner alignment, and easier installation or replacement compared to traditional wooden cleats. They also prevent movement or noise caused by frequent guest use.

A well-built hotel bed from a professional supplier typically lasts 7–10 years, depending on occupancy levels, materials, and housekeeping practices.

MDF absorbs moisture and swells, causing deformation, cracks, upholstery damage, and weakened structural strength. Plywood or HMR (high-moisture-resistant) panels are much more suitable for hotel environments.

Look for certifications like ISO9001, ISO14001, CAL117, BS7177, and structural load-testing reports. These ensure safety, environmental compliance, and long-term durability.

Key factors include material quality, fabric grade, foam density, joinery strength, mounting systems, and packaging. Two beds may look similar but have very different internal structures — this greatly impacts cost.

A mock-up room allows you to test the bedhead, bed base, feature wall, proportions, comfort, and installation method before producing 100–500 units. It prevents design mistakes and expensive rework later.

Make sure all quotes use the same specifications: frame material, thickness, upholstery fabric rub count, foam density, slat type, mounting system, and packaging. Otherwise, you’re comparing products of completely different quality levels.