Blog

How to Choose the Right Hotel Furniture Supplier: A Manufacturer’s Expert Guide

Table of Contents

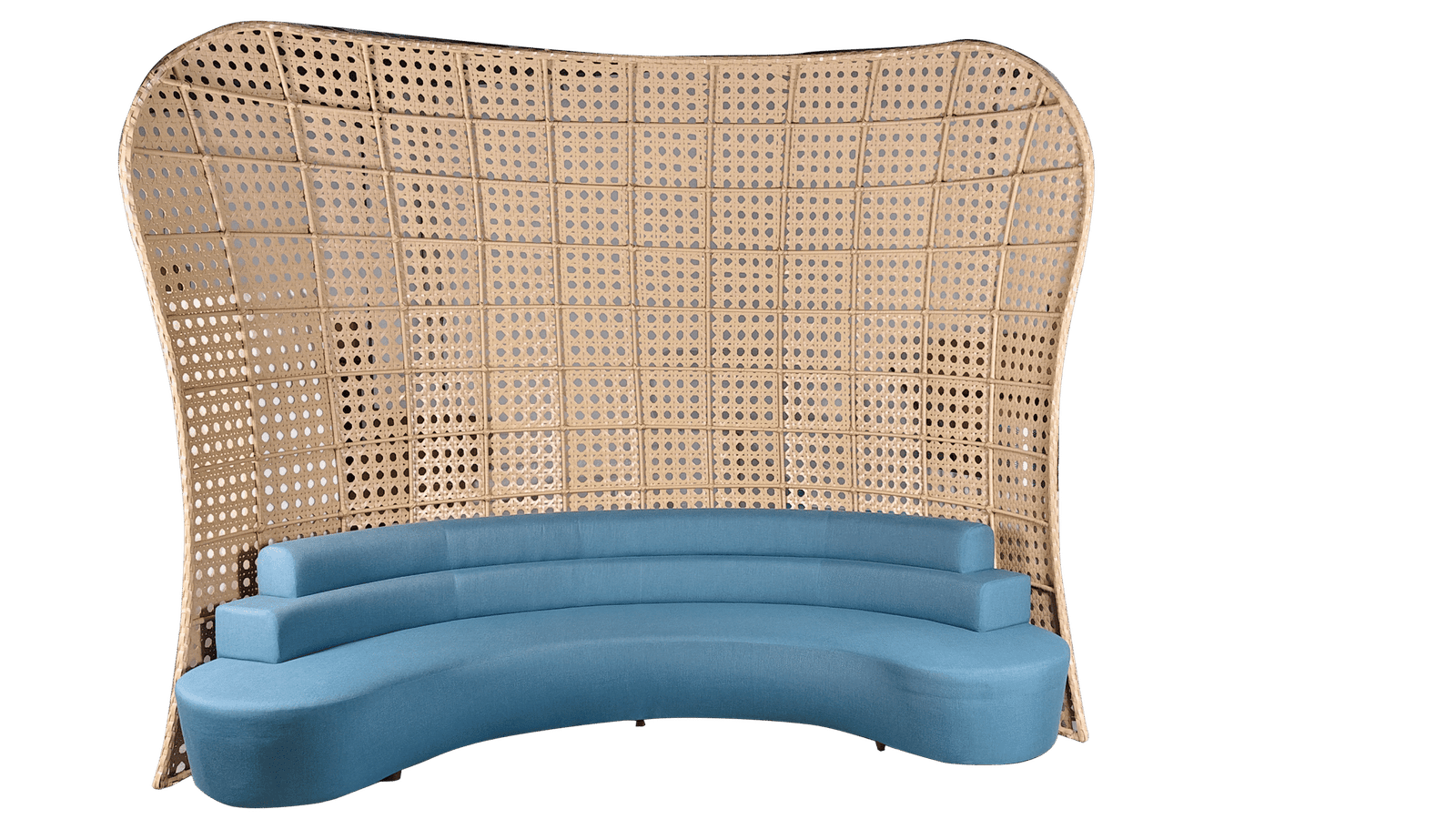

Selecting a hotel furniture supplier isn’t just a procurement task—it’s a strategic decision that affects project timelines, brand compliance, guest experience, and operational durability for the next 5–10 years. In hospitality, furniture is more than décor: it must survive constant wear, local climate, housekeeping chemicals, and repeat guest usage. A wrong supplier can cause budget blowouts, delayed handovers, and costly rework during installation.

As an experienced hotel furniture supplier who has worked with developers, contractors, hotel owners, and international design teams, I’ve seen the patterns behind successful projects—and the root causes of the failures. The truth is simple: most furniture issues are avoidable if you choose the right partner from the beginning.

This guide provides a deeply practical, technically informed roadmap for evaluating hotel furniture suppliers—not based on theory, but based on thousands of rooms manufactured, installed, corrected, and delivered over decades.

┌───────────────────────────────┐

│ 1. MATERIAL CHECK-IN │

├───────────────────────────────┤

│ • Veneer batch verification │

│ • Solid timber moisture check │

│ • Metal thickness inspection │

│ • Foam density confirmation │

│ • Stone / marble defect check │

└───────────────┬───────────────┘

│

▼

┌───────────────────────────────┐

│ 2. WORKSHOP PRE-PRODUCTION │

├───────────────────────────────┤

│ • CNC cutting accuracy test │

│ • Edge banding tolerance check │

│ • Veneer grain direction match │

│ • Metal welding structural test│

└───────────────┬───────────────┘

│

▼

┌───────────────────────────────┐

│ 3. COMPONENT QC │

├───────────────────────────────┤

│ • Panel flatness check │

│ • Upholstery stitching QC │

│ • Hardware positioning test │

│ • Paint adhesion & curing test │

└───────────────┬───────────────┘

│

▼

┌───────────────────────────┐

│ 4. ASSEMBLY INSPECTION │

├───────────────────────────┤

│ • Drawer alignment check │

│ • Door soft-close test │

│ • Weight-load test │

│ • Corner stability test │

└──────────────┬────────────┘

│

▼

┌───────────────────────────┐

│ 5. 30% / 60% / 90% QC │

├───────────────────────────┤

│ • Photo reports to client │

│ • Designer comments fix │

│ • Random sampling │

│ • Tolerance re-check │

└──────────────┬────────────┘

│

▼

┌───────────────────────────┐

│ 6. PRE-PACKAGING QC │

├───────────────────────────┤

│ • Surface scratch check │

│ • Sharp edge removal │

│ • Loose hardware fix │

│ • Quantity check │

└──────────────┬────────────┘

│

▼

┌───────────────────────────┐

│ 7. EXPORT PACKING │

├───────────────────────────┤

│ • 5–7 layer cartons │

│ • 20–30 mm EPE protection │

│ • Corner guards │

│ • Wooden crates for stone │

│ • Room-number labeling │

└──────────────┬────────────┘

│

▼

┌───────────────────────────┐

│ 8. LOADING & FUMI │

├───────────────────────────┤

│ • CBM optimization │

│ • Weight distribution │

│ • Fumigation certificate │

│ • Export docs prepared │

└───────────────────────────┘

What You Need Before You Begin

(Highly Recommended for Accurate Supplier Evaluation)

FF&E schedule or at least preliminary furniture list

Concept drawings or design intent moodboards

Room type quantities and estimated handover date

Brand standards (if under Hilton, Marriott, Accor, IHG, etc.)

Required certifications: ISO9001, ISO14001, FSC, fire ratings

Budget range and VE expectations

Project manager or onsite lead responsible for FF&E coordination

Step 1: Define Your Project Requirements with Professional-Level Clarity

Most hotel projects fail long before production starts. They fail at the definition stage—because unclear scope creates mispricing, misalignment, and manufacturing assumptions that eventually become project risks.

What Expert Suppliers Look For (but Clients Often Forget):

Furniture dimensions that clash with MEP

(Example: minibar height exceeding beam clearance)Unrealistic finishes

Designers sometimes specify veneers or stones that cannot be sourced consistently at scale.Incorrect foam specifications

If not defined early, suppliers may choose cheaper densities.Brand durability requirements

Hilton drawers require different runners than Marriott or Accor.Installation conditions

Furniture may not fit because plasterboard thickness varies or floor buildup changes.

Expert Insight:

A good hotel supplier will request a technical feasibility review before quoting.

This saves 5–12% of total cost by identifying unnecessary specifications, structural weaknesses, and over-engineering.

Step 2: Distinguish a Real Factory from a Trading Company (Most Developers Can’t)

The hospitality sector is flooded with trading companies presenting themselves as factories.

This leads to inconsistent quality, weak QC, unclear responsibility, and higher risk.

What True Factories Have (That Traders Cannot Fake):

CNC machining workshops

Veneer pressing rooms with humidity control

Upholstery workshop with foam cutters & stitching lines

Metal fabrication line (welding, grinding, polishing, PVD)

Paint booth for PU or UV coatings

In-house QC team with calibrated tools

Documented workflow and ISO procedures

What Traders Always Struggle With:

Quality consistency

Solving site issues

Engineering drawings

Fixing production mistakes

Providing spare parts

Providing accurate lead times

Professional Test:

Ask for a live video call walking through:

wood → metal → upholstery → painting → QC → packing.

No trader can pass this test.

Step 3: Evaluate Sample Quality Like a Professional Furniture Engineer

Your mock-up room (MUR) reveals 90% of future mass production issues.

Most developers only look at aesthetics—but experts know what truly matters.

What You MUST Check (High-Level Supplier Checklist):

1. Structural Strength

Chair must pass a 120 kg drop-load test.

Bed base must support 250–300 kg static load.

2. Veneer Consistency & Grain Direction

Poor factories mix different veneer batches → color mismatch in rooms.

3. Foam Density & Longevity

Hotel-grade: 35–45 kg/m³

Cheaper foam sinks after 6 months.

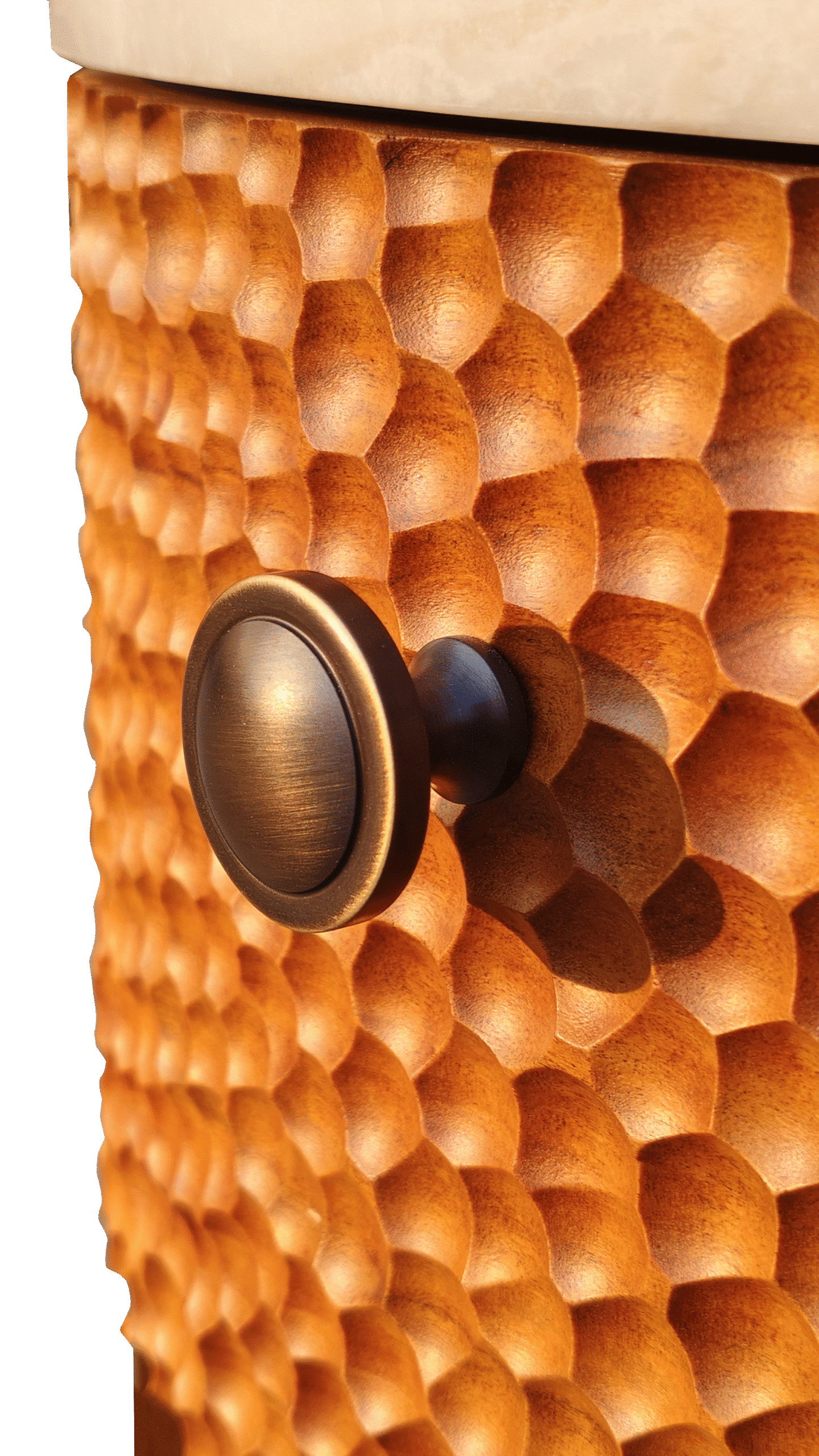

4. Hardware Quality

Use only Hettich, Hafele, DTC, or equivalent.

Low-quality runners cause noisy drawers within months.

5. Paint Durability

UV coating is more scratch-resistant than PU.

Ask for abrasion test results.

6. Edge Precision

±0.5 mm tolerance is the professional standard.

Anything beyond that is visible onsite.

Expert Insight:

Great factories always document sample approval with a sealed finish board, signed by all stakeholders.

This protects you during mass production.

VALUE ENGINEERING (VE) CHART

| Category | Original Specification | VE (Value Engineering) Alternative | Impact |

|---|---|---|---|

| Wood Material | Solid Ash / Solid Oak | Ash veneer + MDF substrate | Same look, 20–35% cost savings |

| Metal Components | Solid stainless steel bar | Stainless steel tube (PVD/brushed finish) | Lighter weight, lower cost |

| Upholstery | Full genuine leather | Half leather + PU on non-contact areas | Maintains appearance, reduces cost |

| Cushion Foam | 45 kg/m³ foam for entire chair/sofa | 45 kg seat + 35 kg back & sides | Same comfort with optimized materials |

| Paint Finish | PU 5–7 layer coating | UV coating | Stronger scratch resistance, lower cost |

| Drawer Runners | Hafele / Blum premium models | DTC soft-close | Good performance with lower cost |

| Bed Base | Full timber slab base | Metal frame + structural plywood beams | Higher strength, lower material use |

| Table Top | Natural marble | Engineered stone / sintered stone | More durable, cost-effective |

| Headboard Core | Full solid wood structure | Plywood + lightweight panel backing | Same stability, lower cost |

| Lighting | Custom integrated lighting modules | Standardized LED modules approved by designer | Easier replacement & maintenance |

Step 4: Analyze Project Management Strength (The True Indicator of Reliability)

Factories rarely fail because of machinery.

They fail because of weak communication.

What You Should Expect from a Top-Tier Supplier:

Shop drawings delivered within 3–5 days

Technical clarifications within 24 hours

Weekly production updates

30% / 60% / 90% QC photo reports

A dedicated PM + QC engineer

Coordination with designers, contractors, and site teams

RFI (Request for Information) system

Red Flags Developers Often Miss:

Short, vague email replies

Incorrect file naming (causes drawing confusion later)

Suppliers who avoid talking about details

Slow sample correction cycle

No comments on potential site tolerance issues

Expert Insight:

The communication quality during quotation is a direct preview of communication during production.

PROCUREMENT RISK MATRIX FOR HOTEL FF&E

| Risk Level | Risk Description | Impact on Project | Recommended Mitigation |

|---|---|---|---|

| HIGH | Supplier is a trading company, not a factory | High defect rate, unreliable QC | Factory audit, workshop videos, verify certifications |

| HIGH | No mock-up room (MUR) before mass production | Design errors, rework costs, delays | Require full MUR + signed finish board |

| HIGH | Incomplete or incorrect shop drawings | Wrong dimensions, mismatched materials | Enforce 3–5 day drawing turnaround, designer sign-off |

| MEDIUM | Weak export packing standards | Damages during shipping | Request packing SOP, packing photos, wooden crates |

| MEDIUM | Veneer color inconsistency | Visual mismatch across rooms | Veneer batch control, ΔE ≤ 1.0 color tolerance |

| MEDIUM | Low QC documentation | Hidden defects, delayed discovery | Require 30% / 60% / 90% QC inspections & reports |

| LOW | Minor hardware substitution | Potential durability issues | Lock hardware brand, grade, and model number in contract |

| LOW | Small dimension deviations | Installation adjustments | Define tolerances clearly (±0.5 mm recommended) |

Step 5: Evaluate Packing, Logistics, and Shipping Like a Global Procurement Expert

More hotel projects face delays and complaints due to poor packing and logistics than poor production.

What Professional Export Packing Looks Like:

5–7 layer export cartons

Custom foam molds

20–30 mm EPE edge protection

Moisture-proof PE film

Corner protectors + edge guards

Wooden crates for mirrors, marble, and lights

Full labeling: room number, floor, item code

Container loading plan for maximum CBM efficiency

What Poor Suppliers Do:

Random packing → chaotic installation

Thin carton → damages

No fumigation → container held at customs

Wrong HS code → tax penalty

Wrong labeling → onsite confusion & delays

Inconsistent CBM planning → higher shipping costs

Expert Insight:

A supplier who saves you 1 container through optimization can reduce cost by USD 2,000–6,000.

That alone can offset price differences between suppliers.

Step 6: Verify Past Experience, Brand Compliance & Reference Projects

Not all “hotel furniture projects” are equal.

Hotel-grade FF&E requires strict standards that normal residential furniture cannot pass.

What You MUST Verify:

1. Chain Brand Experience

Hilton

Marriott

Accor

IHG

Hyatt

Wyndham

Suppliers who passed these have proven engineering capability.

2. Photo Evidence

Compare:

Shop drawings

Mock-up photos

Installation photos

You’ll see if the supplier maintains consistency.

3. Repeat Clients

A supplier with repeated orders from the same developer is worth trusting.

4. References

Ask for contacts from completed projects.

Expert Insight:

Factories with real hotel experience rarely compete on the lowest price—they compete on predictability and zero-defect delivery.

Step 7: Review Contract, Warranty, and After-Sales Procedures with Precision

Contracts must protect you, not the supplier.

What Expert Suppliers Agree to:

Approved samples must be the benchmark for mass production

Clear finishing schedule

Color & tolerance standards

QC inspection checkpoints

Replacement policies

Final acceptance checklist

Warranty of 2–5 years

Spare parts included

Responsibility division for damage (factory vs logistic vs site)

Hidden Contract Risks to Avoid:

No mention of sample as the production benchmark

No tolerance range (allows supplier to argue later)

No delivery penalty clause

No requirement for material certificates

No mention of packing standards

No after-sales response time requirement

Expert Insight:

A contract that includes finish boards, drawing lists, QC forms, and material specifications reduces 80% of future disputes.

Conclusion

A hotel furniture supplier is not just a vendor—it’s a strategic partner responsible for the final “touch and feel” of your hotel rooms. By following the evaluations in this guide, you will dramatically reduce project risk, maintain design integrity, avoid installation delays, and protect your budget.

The right supplier doesn’t just deliver furniture.

They deliver predictability, consistency, technical clarity, and schedule certainty—the elements that turn a hotel project from stressful to successful.

If you’d like help reviewing drawings, value-engineering your project, or preparing a full FF&E procurement plan, I’m happy to assist.

FAQs

You should look for a real factory—not a trading company—with in-house workshops for wood, metal, upholstery, and finishing. Check their past hotel projects, QC workflow, sample quality, export packing standards, and communication speed. A good supplier provides shop drawings within days, offers technical advice, and has clear after-sales support.

A factory manufactures the furniture themselves, ensuring consistent quality, stable pricing, strong QC, and full control over production. A trading company outsources work to different workshops, leading to inconsistent finishes, unclear communication, and higher risk of defects or delays. Always request factory videos or audits.

A mock-up room allows you to verify the design, dimensions, finishes, comfort, material quality, and installation conditions before mass production. More than 80% of issues—such as veneer mismatch, hardware misalignment, or insufficient lighting—are discovered at the MUR stage. It protects your project and prevents expensive rework.

A standard 80–150 room hotel project typically takes:

7–15 days for shop drawings

20–35 days for mock-up room sample

60–90 days for mass production

Lead times depend on design complexity, material sourcing, and approval speed.

Key factors include:

Wood type (solid wood vs veneer)

Metal specifications (solid bar vs tube)

Foam density (especially in sofas and chairs)

Hardware brand (Hettich, Blum, DTC)

Finishing type (PU vs UV coating)

Stone material selection

Custom shapes vs standard forms

Value engineering can reduce cost by 10–25% with no visual impact.

Look for:

Previous 200–500 room projects

In-house production scale (CNC, metal, paint, upholstery)

ISO certifications

On-time delivery history

Weekly production reporting

30/60/90 QC systems

References from developers

If they lack these, the risk increases significantly.

Professional hotel suppliers use:

Material check-in inspection

Veneer colour batch control

CNC accuracy tests

Panel flatness & edge tolerance check (±0.5mm)

Upholstery stitching QC

Paint adhesion test

Hardware load test

30% / 60% / 90% QC inspection

Pre-packaging QC

Full packing documentation

This ensures consistency in all rooms.

Correct export packing includes:

5–7 layer export cartons

20–30mm EPE foam protection

Corner guards and edge protectors

Moisture-proof PE wrapping

Wooden crates for stone, mirrors, or lighting

Room-numbered labeling

CBM-optimized container loading

Proper packing prevents the majority of shipping damage.

Key certifications include:

ISO9001 (Quality Management)

ISO14001 (Environmental Management)

FSC (Sustainable wood)

Fire rating compliance: CRIB 5, CAL TB117, BS5852

VOC compliance for paint

Hotels under Accor, Hilton, Marriott, and IHG often require these.

Yes. Value engineering focuses on hidden structures, not visible surfaces.

Examples:

Replace solid wood with veneer + MDF

Use metal tubes instead of solid bars

PU/UV coating instead of PU multi-layer

Standardized LED modules instead of custom lights

A professional supplier can reduce cost 10–25% while keeping the same look.

Common reasons include:

Late shop drawing approval

Incomplete design information

Designer or owner changes

Incomplete MEP coordination

Incorrect site measurements

Delayed payment milestones

Shipping congestion

A strong supplier manages these risks early.

Compare more than just price. Check:

Materials & finish specifications

Hardware brand

Panel density and thickness

Frame construction

Packing standards

QC workflow

Project management capability

Real factory photos vs stock photos

Cheaper quotes often hide weaker specs.

Yes. Hotels in humid climates (Southeast Asia, Caribbean, Pacific Islands) require:

E0/E1 plywood

UV-coated surfaces

Anti-rust metal

Mold-resistant foam & fabric

Moisture-resistant veneer

Ignoring climate conditions leads to warping and mold.

Standard warranties range from 2 to 5 years, depending on the product category.

Premium suppliers offer:

Free replacement for structural defects

Quick after-sales response

Spare parts included

Avoid suppliers offering no written warranty.

Good suppliers provide:

Shop drawings matched with MEP layout

Fixing details for wall panels & headboards

Installation manuals

Room-by-room packing lists

Coordination for site tolerance adjustments

Online meetings during installation

This prevents installation delays and misalignment.