Blog

Hotel ROI Strategy 2026: How Smart FF&E Furniture and Lighting Choices Protect Your Investment

Table of Contents

In hotel development, every detail — from the veneer on a headboard to the LED behind a mirror — affects your return on investment (ROI).

When casegoods crack, lights flicker, or drivers fail, it’s not just a maintenance issue — it’s lost ROI through downtime, rework, and guest dissatisfaction.

This guide shows how FF&E furniture and lighting materials directly shape your ROI, exposes common industry shortcuts that drain value, and demonstrates how Betherev’s integrated one-stop factory helps developers achieve measurable financial resilience.

Why FF&E Finishes and Lighting Fail — and How It Hurts ROI

The Question:

Why do brand-approved rooms lose their “new” look within three years?

Common Industry Solution:

Most vendors source furniture and lighting separately. Furniture makers cut corners on MDF or thin veneer; lighting vendors supply mismatched LED drivers or low-CRI strips.

The result: fading colors, uneven tones, premature lamp failures — all forcing early replacement.

Betherev’s ROI-Driven Solution:

Betherev engineers both E0-grade plywood furniture and UL/CE-certified LED systems under one roof.

By controlling materials and circuits together, we prevent warping, color shift, and voltage mismatch.

Projects using this integrated model show 9- to 11-year service life for furniture and > 20 000 h burn-in-tested lighting, extending asset ROI by 30 %.

How to Cut Maintenance Costs Without Downgrading Quality

The Question:

Can you reduce housekeeping and maintenance budgets without sacrificing brand standards?

Common Industry Solution:

Developers often choose “scratch-proof” laminates and off-the-shelf light fixtures. Within a year, coatings dull and lights yellow, demanding constant polishing and bulb changes.

Betherev’s ROI-Driven Solution:

We use high-pressure laminates (HPL) with anti-fingerprint nano-coatings and 24 V LED systems with Dupont connectors for quick swap-outs.

This combination reduces maintenance labor by 40 % and replacement parts cost by 25 % annually.

In Waldorf Astoria Costa Rica, integrated casegoods + back-lit mirrors cut total OpEx by USD 38 000 per year across 250 rooms.

How to Align Design Vision and Production Practicality

The Question:

Designers specify walnut gloss and warm-white lighting — factories say it’s unstable or unavailable. Who’s right?

Common Industry Solution:

Late color or temperature changes cause mismatched finishes and inconsistent ambience, delaying openings.

Betherev’s ROI-Driven Solution:

Betherev’s digital color-match database synchronizes wood finishes (ΔE ≤ 1.0) with LED color temperature (3000 K ± 100 K).

Mock-ups are approved within three weeks — 60 % faster than average — maintaining aesthetic intent and manufacturability.

For Mercure Flagstaff Melbourne, this alignment prevented six weeks of delay worth USD 180 000 in lost revenue.

How to Ensure Compliance and Brand Audit Readiness

The Question:

How can you guarantee every furniture and lighting component passes brand audits and safety checks?

Common Industry Solution:

Trading companies issue outdated fire or electrical certificates. When brands audit, half the documentation fails — leading to penalties and resubmission.

Betherev’s ROI-Driven Solution:

Every Betherev shipment includes a digital QC dossier with:

BIFMA mechanical tests for furniture

CRIB 5 / CAL 117 fire certificates for fabrics

UL / CE / CSA certifications for lighting

ISO 9001 & 14001 quality + environmental systems

This end-to-end transparency achieves zero audit rejections and shortens approval cycles by 30 %, safeguarding brand credibility and hotel valuation.

How FF&E Furniture and Lighting Drive Hotel ROI

| ROI Lever | Integrated Material Impact | Typical ROI Gain |

|---|---|---|

| CapEx Efficiency | Engineered wood + LED modules share production logistics | +15 % lifecycle ROI |

| OpEx Reduction | Durable finishes + long-life LEDs cut service calls | +12 % annual ROI |

| Energy Efficiency | 24 V LED + dimming saves > 25 % electricity | +8 % utility ROI |

| Asset Value Retention | Coordinated finish + lighting color consistency | +10 % resale ROI |

| Brand Compliance | Single-factory QC, zero rework | +5 % schedule ROI |

Challenge: 6-year-old furniture fading; lighting color inconsistency hurting guest ratings.

Common Response: Replace furniture and lighting separately — double CapEx.

Betherev’s Strategy: Replace marble tops with sintered stone, refit spaces with matched 3000 K LED strips.

Result:

18 % CapEx savings

4-year extension of refurbishment cycle

Zero room downtime during warranty

+26 % total ROI improvement over 10 years

Final Thoughts

For developers, durability and integration equal profit.

By aligning furniture materials and lighting technology within one manufacturing ecosystem, Betherev turns FF&E from a cost line into a capital growth tool.

You protect ROI through reduced downtime, predictable maintenance budgets, and consistent brand presentation that guests — and investors — trust.

Next Step: Request a Hotel ROI Consultation

Book a 20-Minute FF&E + Lighting ROI Session

Review your specifications with Betherev’s one-stop factory for joinery + lighting and receive a custom Hotel ROI Report comparing CapEx, energy use, and replacement cycles.

Explore our hotel furniture case studies and download your FF&E Project Timeline Template (Excel) to plan your next build efficiently.

FAQs

Furniture, fixtures, and equipment (FF&E) make up a major portion of a hotel’s CapEx. When materials fail early, they increase maintenance costs and shorten refurbishment cycles. Choosing engineered woods, high-pressure laminates, and certified fabrics extends the lifecycle and reduces long-term OpEx — directly improving hotel ROI over 10 years.

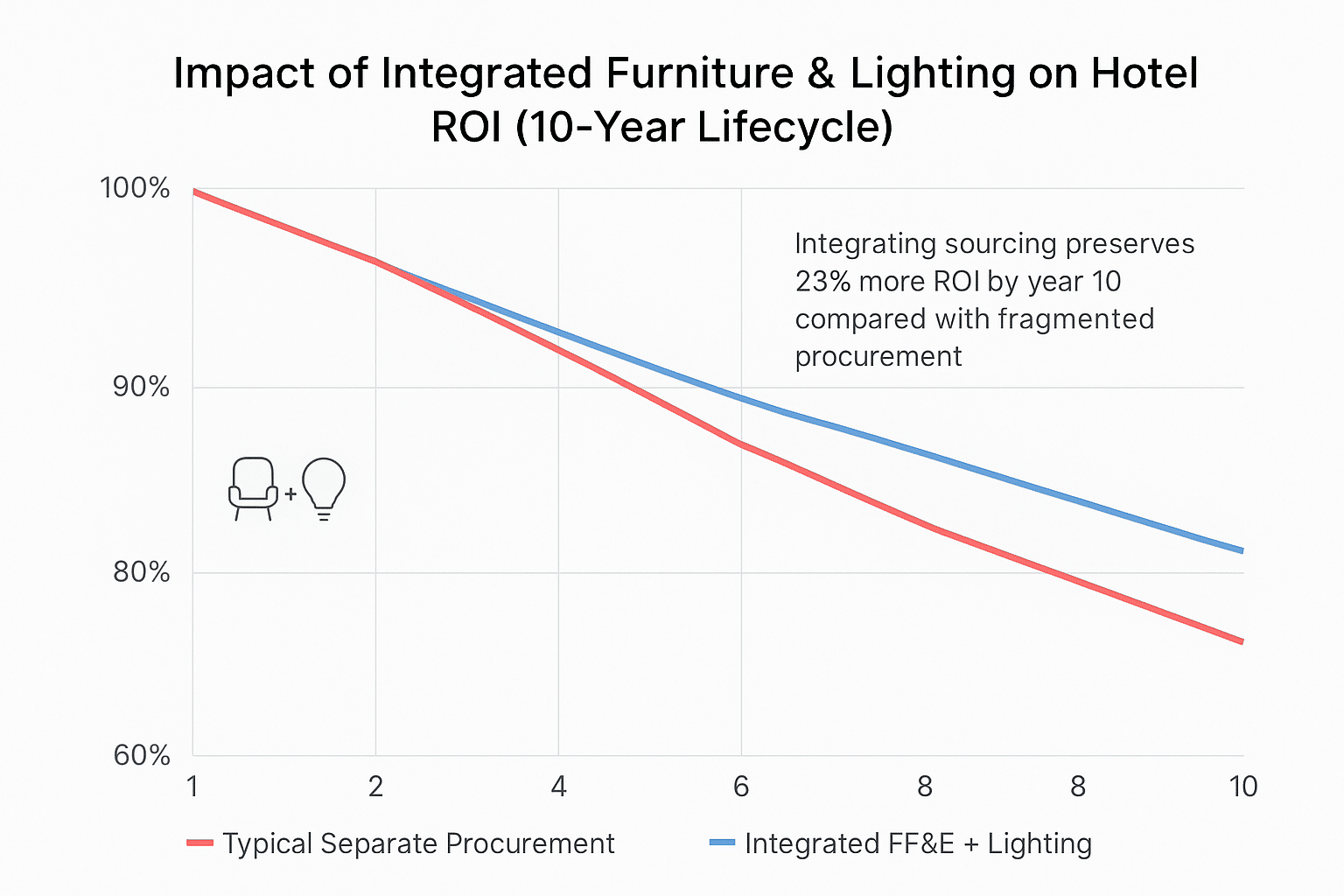

When FF&E and lighting are sourced from different suppliers, mismatched finishes, color tones, and inconsistent installation schedules are common. Integration ensures synchronized design, consistent quality, and shared logistics — cutting project lead times and preserving 20–30% more ROI through reduced rework and downtime.

Hotels achieve better ROI with 24 V LED systems, 3000 K ± 100 K warm color temperature, CRI > 90, and Dupont quick-connect plugs. These features minimize voltage loss, reduce labor during installation, and lower power consumption by up to 25 %, extending system life beyond 20 000 hours.

Always request a digital QC dossier that includes:

BIFMA strength reports for furniture

CRIB 5 / CAL 117 fire certificates for fabrics

UL / CE / CSA certifications for lighting

ISO 9001 + 14001 compliance for manufacturing

Betherev provides all documentation in one verified pack, ensuring zero audit rejections.

Based on Betherev’s project data across Hilton, Marriott, and Accor hotels, integrated sourcing improves ROI by 20–35 % over a 10-year cycle — achieved through longer product lifespan, fewer replacements, and smoother brand approvals.

Late approvals, incompatible lighting specs, or non-certified materials can trigger rework, shipment delays, and brand audit failures. Each week of delay can cost USD 30 000–80 000 in lost pre-opening revenue for mid-scale properties. Early coordination between design, engineering, and production prevents these losses.

Betherev evaluates ROI using a 10-year lifecycle cost model, comparing CapEx, maintenance, and replacement expenses. The analysis quantifies savings from:

Reduced rework cost

Shorter installation time

Energy savings from efficient LEDs

Extended refurbishment intervals

Developers receive a custom Hotel ROI Report outlining tangible cost benefits.

Treating FF&E as a one-time expense, not an investment

Sourcing lighting separately from furniture

Ignoring long-term maintenance cost in material selection

Accepting incomplete certification packages

Rushing mock-up approvals without performance tests

Ideally at the concept or schematic design phase — 8–10 months before handover. Early ROI modeling allows design and engineering teams to select materials and lighting systems that achieve the best CapEx/OpEx balance.

Betherev is a one-stop factory integrating custom furniture, joinery, and lighting. With ISO-certified QC, digital documentation, and 30 + years of project experience, the company helps hotel owners plan, manufacture, and deliver FF&E packages that protect ROI, brand reputation, and long-term asset value.