Blog

How to Create a Hotel Refurbishment Plan That Reduces Cost, Delays, and Guest Impact

Table of Contents

Most hotel refurbishments go over budget, over schedule, or quietly damage guest satisfaction. But it doesn’t have to be this way. A strong hotel refurbishment plan can save months of delays and millions in lost revenue.

In this guide, you’ll learn how to plan, budget, schedule, and execute a hotel refurbishment plan with fewer surprises, smoother approvals, and tighter cost control — all using real-world practices from global hotel projects.

What a Hotel Refurbishment Plan Should Include (And Why Most Hotels Miss Key Steps)

A solid hotel refurbishment plan doesn’t start with demolition or design — it starts with clarity. When you know exactly what you’re updating, what it will cost, and how long it will take, the whole project becomes easier to manage. Most delays come from the early planning stage, not the actual construction.

A complete plan usually covers a few core components. You need a clear scope so everyone agrees on what’s being renovated. Then you need budgets, timelines, and the approval flow — who signs off on what, and when. After that comes procurement, FF&E/OS&E coordination, and checking compliance with fire codes, accessibility rules, and brand standards. When any one of these pieces is missing, the whole project slows down.

Hotels often fail because the “invisible” groundwork is skipped. A lot of teams jump straight into design without doing proper surveys or documenting the existing conditions. This leads to unclear scope, mismatched measurements, and even conflicts with the brand’s latest requirements. When the design doesn’t match reality, someone has to redo drawings or re-specify materials, and that’s when things spiral.

There are a few documents you absolutely need before the project even begins. As-built drawings, proper condition surveys, and MEP (Mechanical, Electrical, Plumbing) checks are the minimum. These documents tell you what’s really on-site — not what the old drawings say is on-site. Even small differences, like a beam being 40mm lower than expected, can change the entire FF&E layout.

Identifying high-risk areas early can save you weeks. Guest rooms, wet areas, integrated joinery, and anything touching MEP services are usually the trouble spots. If the project includes new lighting, plumbing shifts, or built-in joinery, you want those areas inspected first. That’s where hidden issues like water leaks, uneven floors, or old wiring usually show up.

Here’s a real example. A developer once skipped a proper wall survey for a guest room renovation. Everyone assumed the existing walls were straight and true. They weren’t. When the new bedhead panels arrived, they didn’t fit because one wall bowed nearly 15mm. The contractor had to stop work, re-level the wall, and wait for adjusted joinery. That small oversight added six weeks to the construction schedule — and cost the project thousands in additional labor and rework.

A good hotel refurbishment plan isn’t complicated. It’s just disciplined. The more you confirm upfront, the fewer surprises you get when the work starts. And in hotel projects, surprises are what kill your timeline.

Setting a Realistic Budget for Your Hotel Refurbishment

Setting a budget for a hotel refurbishment isn’t just about picking a number and hoping everything fits. You need to understand what actually drives cost, or the whole project can slide off-track fast. And once a hotel misses its reopening date, the financial pain is real.

The biggest cost drivers are usually FF&E, joinery, and any upgrades to MEP or fire systems. These aren’t “nice-to-haves”—they’re the things that keep the hotel functional and compliant. Finishes, logistics, and site conditions also add up quickly, especially if you’re dealing with tight access, old buildings, or night-shift labor. When one of these areas blows out, the rest of the budget has to stretch to cover it.

One thing I always suggest: start value engineering before you send the package to tender, not afterward. Early VE lets you adjust materials, simplify details, or rework joinery structures before contractors price it. Late VE is where budgets go to die—everything is rushed, no one has time to compare options, and quality often takes the hit.

Hotels also forget the soft costs. Design fees, permits, mock-ups, temporary storage, and installation labor sound small compared to FF&E, but together they can run into six figures. And mock-up rooms aren’t optional—you want the mistakes caught early, not repeated across 200 keys. The more detailed your soft-cost list is, the less shock you’ll face later.

How you structure the budget also affects clarity. Room-by-room budgeting works well for guest rooms because it helps you see exactly how each detail adds up. Zone-by-zone budgeting is better for public areas since each space has different requirements. Some teams prefer package-based budgeting—FF&E, lighting, flooring, joinery—so they can track each major scope easily. The best method is the one that makes it easiest for your team to catch problems early.

Lastly, keep a 10–15% contingency, but use it intentionally. Contingency isn’t a “bonus fund” for last-minute design changes. It’s there for hidden defects, price fluctuations, or things no one could’ve predicted behind a wall or slab. When you treat the contingency as protection instead of spending money, the whole project stays calmer and more controlled.

Timeline Planning: How to Minimize Guest Disruption and Lost Revenue

A good refurbishment timeline isn’t just a Gantt chart. It’s a plan for how to keep the hotel earning money while you upgrade it. When you understand how long each stage really takes and where the risks are, you can make choices that protect revenue instead of stopping it.

One of the smartest ways to plan is by choosing the right phasing strategy. You can renovate by floors, by wings, by zones, or by clusters of rooms that share the same MEP services. Each approach changes how much revenue you lose and how smoothly contractors can work. For example, doing work by clusters helps control noise and dust, but doing work by full floors lets you finish whole zones faster. There’s no “perfect” choice—it depends on occupancy, layout, and how sensitive your guests are to disruption.

It also helps to understand how long major tasks typically take. Demolition might take a few days, especially in older buildings with surprises behind walls. MEP work—plumbing, electrical, air-conditioning—often takes the longest because everything must be installed, tested, and inspected. Finishes like painting and flooring move faster but require dry times. FF&E installation looks quick on paper but can stretch out when joinery needs adjustments or access is tight. When you know these rhythms, your timeline becomes realistic instead of hopeful.

Every timeline needs buffers. And not tiny ones—real buffers.

You need space for inspections, small reworks, material delivery delays, and shop drawing updates after site discoveries. These buffers protect the project from slipping into peak season or high-occupancy periods. Without them, hotels scramble, revenue drops, and the team gets blamed for “delays” that were predictable from day one.

Working in a live hotel adds its own layer of complication. You’ll deal with noise restrictions, guest corridors that must stay clean, limited lift access for materials, and tight staging areas where furniture and joinery need to sit before installation. Sometimes contractors can only work between certain hours, which slows everything down. You need a plan that respects the guest experience while still keeping progress moving.

Here’s a quick example.

A 200-room hotel might plan refurbishment in 3-floor phases, each taking about 4 weeks. That means roughly 40–50 rooms offline at a time instead of the whole building. Revenue stays alive. The construction team gets enough space to work efficiently. And because the phases are predictable, the hotel can plan promotions, moves, and guest communication around each block of rooms.

This is how you create a timeline that works in real life—not just on paper.

Working With Your FF&E Supplier for a Smooth Refurbishment

Most hotels think construction delays are the main problem, but FF&E is usually the real timeline killer. Nearly 70% of refurbishment schedule issues come from slow approvals, late decisions, or unclear specifications. When a supplier can’t start production because drawings or materials aren’t confirmed, the entire project starts sliding—sometimes by weeks. The good news? You can prevent most of these delays with better planning and clearer coordination.

Shop drawings and sample approvals are two steps that almost always take longer than people expect. Drawings go back and forth between designers, PMs, and brands, and every round adds days. It helps to set fixed review windows—five days for drawings, three days for samples—so everyone knows the expectation. Treat these approvals like critical milestones, not “admin tasks.” When the samples and drawings are confirmed early, production becomes predictable instead of chaotic.

It also matters how you time demolition with production. If you start ripping out rooms before the supplier is halfway through manufacturing, you’ll create long stretches of empty rooms with no furniture ready to install. A better approach is to confirm: When will the factory finish? When will the goods ship? When does installation start? Align those three dates, and you avoid unnecessary revenue loss from rooms sitting idle.

Value engineering (VE) is another tool that can help keep both cost and pressure under control. Small changes—like switching veneer species, adjusting metal thickness, or simplifying joinery—can save money without compromising the design. The trick is to involve the supplier early instead of waiting until pricing blows out. A good factory can propose smart alternatives that maintain the look while keeping the budget in check.

Finally, don’t leave logistics planning until the last minute. You’ll want to think about container scheduling, avoiding weekend arrivals (which create extra port fees), and making sure installation teams have manuals and shop drawings on hand before materials arrive. The smoother your logistics plan, the faster the rooms can get back into service—and the fewer surprises you’ll face once everything lands on-site.

If everything is aligned—approvals, production, VE, and logistics—you’ll notice something: your refurbishment suddenly feels predictable. And predictability is what keeps revenue flowing.

Procurement Strategy: Local vs Overseas Suppliers

Choosing between local and overseas suppliers isn’t always a simple cost comparison. Each option has strengths that show up differently depending on your project timeline, design complexity, and risk tolerance. The goal isn’t to pick one side forever — it’s to choose the model that protects your schedule and your budget for this project.

China manufacturing can reduce your overall cost without hurting quality, especially for large-volume hotel FF&E. When a factory has integrated workshops — wood, metal, upholstery, painting, lighting — they control every step in-house. That’s why consistency stays high and prices stay stable. If your project has 200+ rooms or heavy joinery, overseas manufacturing often saves 20–40% while still meeting brand standards.

Local suppliers, on the other hand, win on speed. They’re close to your site, so lead times shrink dramatically. Even if their unit cost is higher, the shorter timeline can protect your opening date, which is usually worth more than any savings. Local makers are also useful for last-minute items, corrections, or specialty pieces your offshore supplier might not turn around quickly.

That’s why many hotels use a hybrid procurement model: bulk items from overseas and specialty or high-touch items from local suppliers. For example, you might source all guest-room furniture from China but produce mirrors, lighting fixtures, or custom upholstery locally to speed up installation or match last-minute design changes. This keeps your big-ticket costs low while giving you flexibility on-site.

When you’re evaluating suppliers, look at things that matter in real hotel projects:

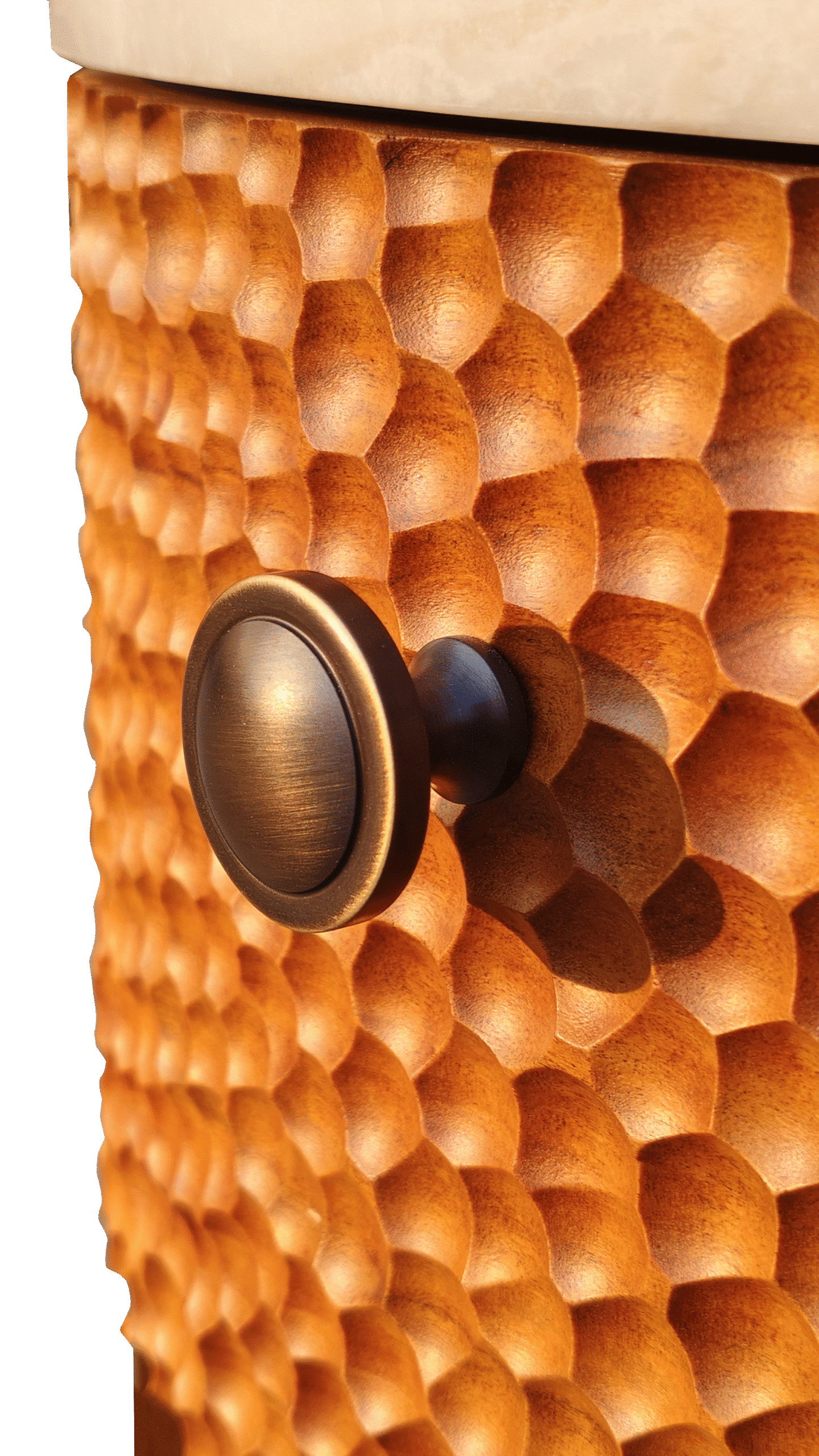

• Past hotel references and whether they match your brand level

• Factory capabilities — integrated workshops vs subcontracted production

• Lead times based on actual workload, not promises

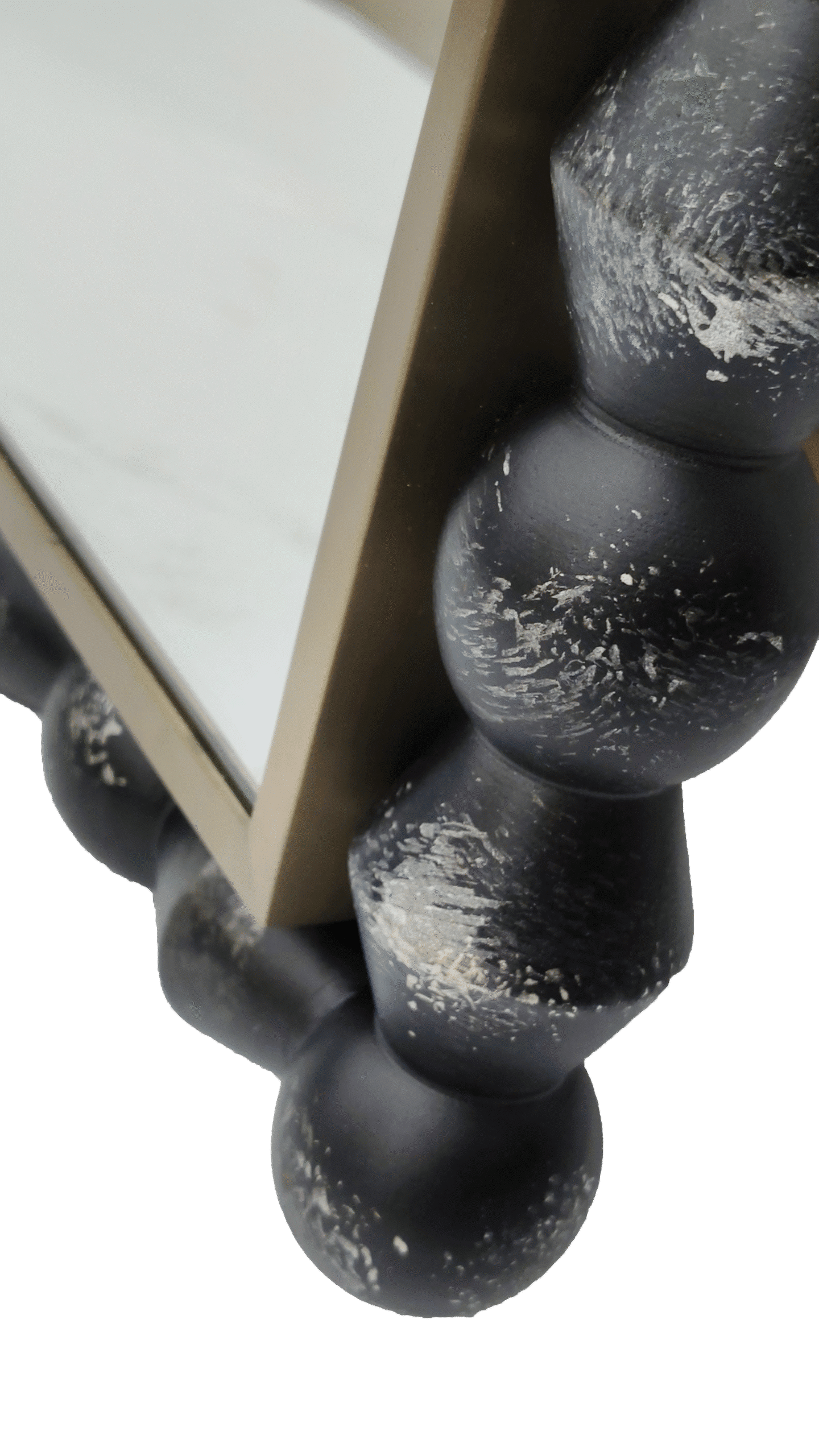

• Sample quality and how closely it matches the final product

• QC workflow — mock-up → 30% → 60% → 90% → pre-shipment

A few red flags are worth calling out. If a supplier subcontracts most of the production, you risk inconsistent finishes and missed deadlines. Mismatched samples — especially color or veneer tone — show weak internal control. And if there’s no established QC system, you’re essentially trusting luck to deliver your hotel on time.

Compliance, Brand Standards, and Approvals

Compliance work is the part nobody sees, but it influences almost every decision you make during a refurbishment. Fire safety, MEP, and accessibility rules often end up dictating where walls, joinery, and even small details like switches or signage can go. If a wardrobe is too deep or a vanity blocks circulation space, it isn’t “just a small adjustment”—it becomes a compliance issue that slows everything down. Getting these items right early saves weeks of rework later.

Fire, MEP, and accessibility requirements also shape the furniture layout more than most people expect. You might want a beautiful floor-to-ceiling panel behind the bed, but fire-rated walls, sprinkler head distances, or conduit routes may force you to adjust the design. The same thing happens with accessibility rooms—simple things like mirror height or handle type suddenly require a rethink. When these details show up late, they trigger design changes, factory updates, and new approvals.

Brand standards add another layer of complexity because they’re written for “ideal” scenarios, not real buildings. Many hotels are older, have non-standard room shapes, or come with existing MEP points that don’t match the brand’s handbook. That’s why brand standards often clash with what’s physically possible on site. The trick isn’t to force everything to match—it’s to document the gap clearly and propose a sensible alternative.

A deviation list is your best friend here. It’s a simple table that shows:

• the brand’s requirement

• the existing site condition

• your proposed solution

• the reason the deviation is needed

When you present this clearly, the brand reviewer usually says yes—because they can see the logic. Don’t wait until after the mock-up to prepare this list. Start it as soon as you compare the brand manual with the measured drawings.

Documentation is what keeps everyone aligned. Designers need updated drawings, the factory needs mock-up comments, the brand needs certificates, and the contractor needs installation guidance. Good documentation includes shop drawings, mock-up reports with photos, test certificates for fire-rated or electrical items, and updated revision logs. Clear paperwork makes approvals smoother and protects you when changes come from outside your control.

In hotel brands like Marriott, Accor, and Hilton, the refurbishment approval cycle is usually longer than people expect. Each brand has its own review team, and they often return comments in batches—first on concept, then on room layout, then on FF&E, then on materials. A typical cycle looks like: submit → wait two weeks → receive comments → resubmit → wait again. If you’re lucky, it takes one or two rounds; if not, it can stretch to four or five. That’s why you plan for approvals early and treat them as a key part of your project timeline rather than an afterthought.

Conclusion

A hotel refurbishment plan isn’t just a schedule — it’s a risk management system. When you combine accurate surveys, realistic budgets, strong FF&E planning, and smart phasing, your refurbishment moves faster, costs less, and keeps guests happier.

If you’re preparing a refurbishment project, start by building your scope and budget — or ask for a supplier-ready checklist to avoid the biggest mistakes.

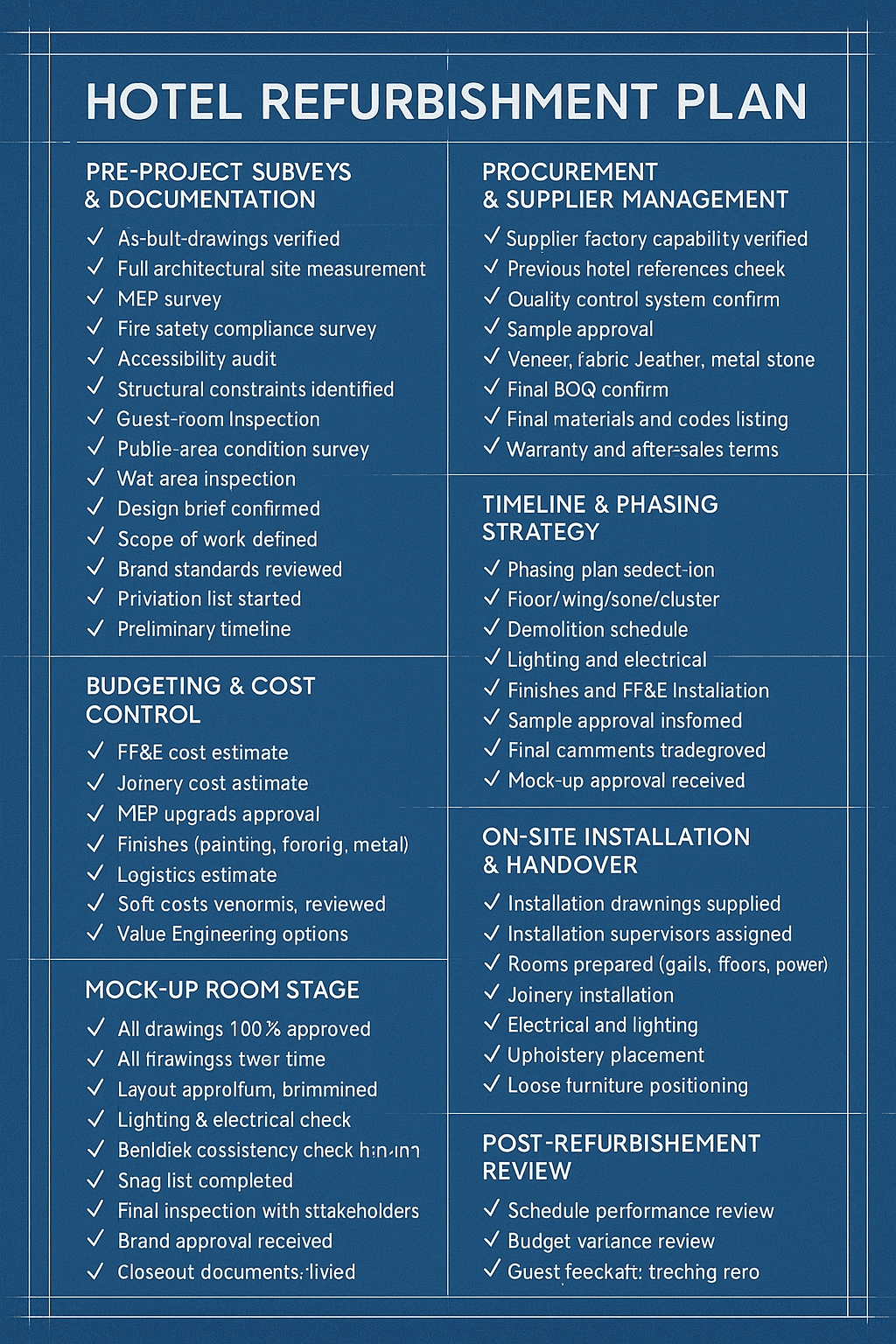

Hotel Refurbishment Plan Checklist

Use this checklist to ensure your refurbishment runs smoothly, stays on budget, and avoids major timeline risks.

If you’re preparing a refurbishment project, start by building your scope and budget — or ask for a supplier-ready checklist to avoid the biggest mistakes.

Download Hotel Refurbishment Plan Checklist

FAQs

A hotel refurbishment plan is a structured roadmap that outlines the scope, budget, timeline, procurement, compliance requirements, and FF&E strategy needed to renovate a hotel on time and within budget.

Most hotel refurbishments take 8–20 weeks, depending on room count, complexity, MEP upgrades, and brand approval cycles. Phasing and pre-planning significantly reduce timeline risks.

The most common causes include incomplete site surveys, slow FF&E approvals, unclear specifications, late material decisions, and unexpected MEP or fire compliance issues.

Use phasing strategies (floors, wings, clusters), strict noise windows, clear guest communication, and optimized logistics to keep downtime and complaints to a minimum.

Start with detailed surveys, prioritize FF&E and joinery, include soft costs, plan mock-up rooms, and hold a 10–15% contingency for hidden defects or unexpected conditions.

Both have benefits. Overseas manufacturers reduce cost for volume FF&E, while local suppliers offer speed and flexibility. Many hotels use a hybrid model to balance both.

Major hotel brands like Marriott, Accor, and Hilton require design, material, and FF&E approvals to ensure compliance with their global standards. Delays in approval directly impact timeline and cost.