Blog

Hotel LED Light Strips That Speed Up 5-Star Builds

Table of Contents

Every hotel developer knows the pain: delays pile up because someone’s still waiting for wiring. Electricians spend hours connecting hotel LED lighting strips, wall switches, or bedside LEDs on-site. Each small coordination mistake means rework, late nights, and extra labor bills.

Now imagine a different setup — one where the custom hotel lighting is already built into the furniture. The wardrobes, mirrors, and headboards arrive with plug-and-play low-voltage hotel LED light strip systems, factory-tested and ready to connect. No open wires. No site improvisation. Just connect the power and go.

That’s where the new generation of factory-integrated hotel lighting changes everything. These systems don’t just make the space look sleek — they save time, reduce safety risks, and simplify the entire construction process.

At Betherev, a leading hotel and hospitality LED lighting supplier, we’ve taken this idea further. Our integrated FF&E + lighting model merges joinery, loose furniture, and custom hotel LED lighting into one production line. The result?

• Shorter project timelines

• Lower electrician and coordination costs

• Perfect brand consistency from room to room

In this article, you’ll see how this approach helps developers, project managers, and interior designers build hotels faster — without compromising design or quality.

Why LED Light Strips Are the Core of 5-Star Hotel Lighting

Walk into any 5-star hotel room and you’ll notice something subtle but powerful — the light feels balanced, calm, and intentional. That’s not by accident. High-end hotels follow a layered hotel lighting design approach, combining ambient, task, and accent lighting to create depth and mood. Ambient light fills the space softly. Task lighting supports practical needs like reading or grooming. Accent light — often delivered through hidden hotel LED light strips — highlights textures, materials, and architecture.

Hotel LED lighting is the backbone of this system because it delivers all three layers effortlessly. It uses 60–70 % less energy than traditional lamps and lasts up to 50 000 hours before replacement. For developers and operators, that means lower electricity bills, fewer maintenance calls, and less downtime — all while meeting sustainability goals that global hotel brands demand.

Color consistency is another key reason 5-star hotel lighting relies on LED strips. Premium installations maintain 3000 K ± 100 K warm white tones across every room, ensuring that whether you’re in Sydney or Dubai, the brand’s lighting identity feels the same. This consistency reinforces brand trust and guest comfort — subtle, but essential.

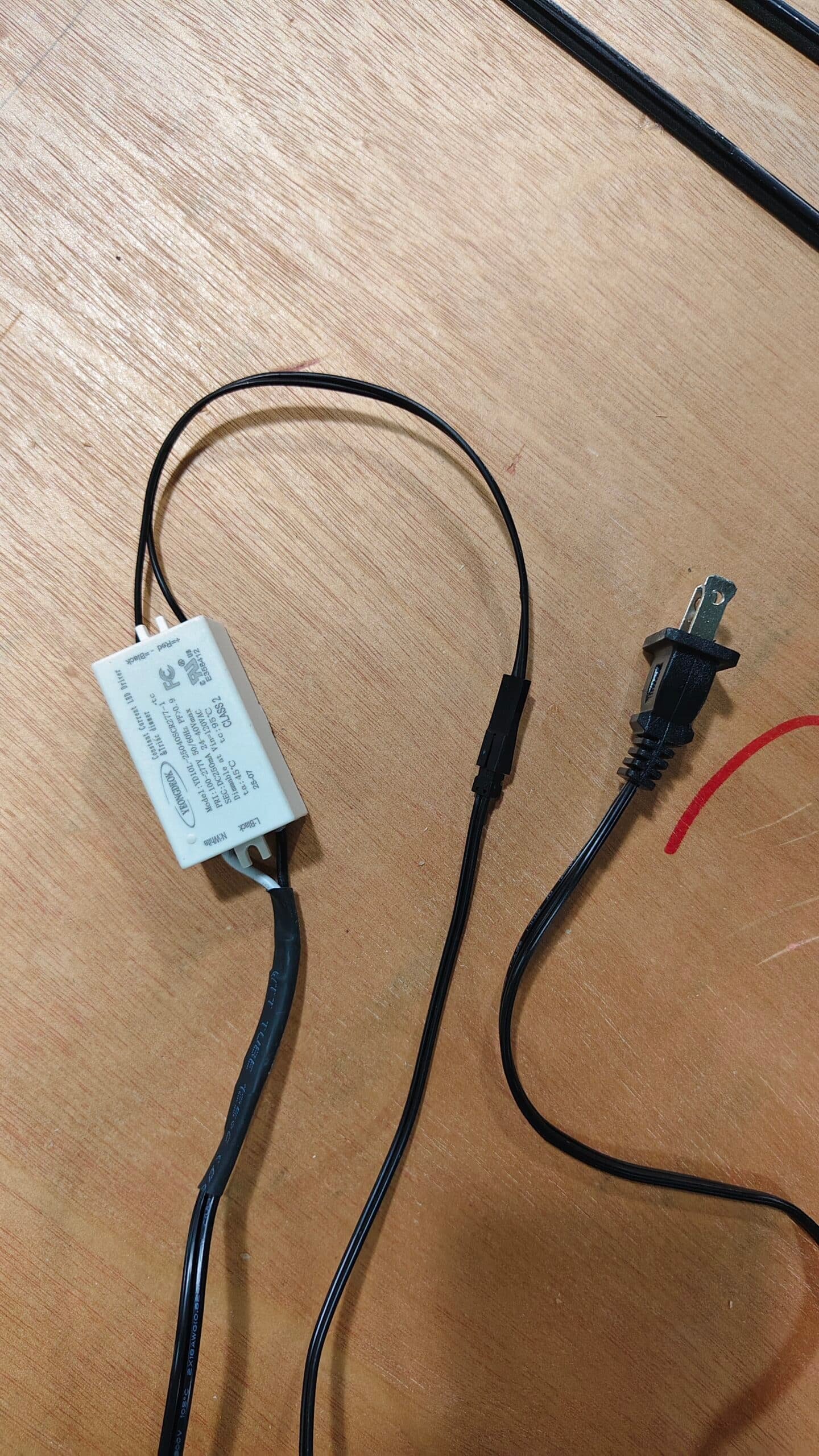

Most hotels now specify low-voltage hotel lighting systems (12 V / 24 V) because they meet CE and UL safety standards and simplify installation. Builders can connect strips with plug-and-play drivers, reducing on-site electrical work and avoiding costly rework. When lighting is coordinated early with joinery and furniture design, it also prevents MEP clashes — one of the most common causes of timeline delays and budget overruns in hotel builds.

In short, well-planned hotel LED lighting isn’t just decorative. It’s a quiet powerhouse — saving energy, aligning brand aesthetics, and streamlining project delivery.

Real-World Integration — From FF&E Drawing to Installed Strip

When hotel room lighting and furniture are designed together, everything fits seamlessly — and that’s where real efficiency starts. Coordinating lighting and joinery drawings upfront prevents the classic on-site chaos: mismatched cutouts, exposed wires, or last-minute carpenter fixes.

At Betherev, we handle this coordination during fabrication. Wiring paths, aluminum channels, and LED housings are all pre-routed inside the furniture before it leaves the factory. That means when the pieces arrive on site, installation is mostly a matter of connection, not construction.

You’ll see this approach most clearly in built-in applications — under-bed coves, vanity mirrors with backlit halos, wardrobe internal LED strips with door sensors, and headboards with soft accent lighting. Each hotel room LED lighting element feels like part of the furniture, not an afterthought.

Because these systems are plug-ready and low-voltage, local electricians spend far less time on site. In one 200-room hotel project, this integration model saved over 150 hours of electrical labor — proof that smart factory planning can literally shorten your project timeline.

Cost-Saving Innovation — Dupont Connectors in Hotel LED Lighting

When it comes to large hotel lighting projects, even a small detail like how light strips connect can make a big difference. Dupont male–female connectors turn hotel LED lighting installation into a true plug-and-play process — no soldering, taping, or on-site guesswork required. For installers and project managers, that means faster progress, fewer mistakes, and a cleaner finish.

Each joint using Dupont connectors saves roughly 15–20 minutes of labor. Multiply that across a 200-room build, and you’re looking at €10 000 or more in labor savings — not to mention reduced fatigue and rework for electricians. For developers managing tight timelines, those minutes translate directly into days gained on the overall schedule.

The system is CE / UL compliant, ensuring no exposed copper and cooler, safer operation over time. These connectors work best with low-voltage 12 V or 24 V hotel LED light strips, which are standard for interior hotel use. The combination keeps energy draw low and safety margins high — ideal for hotel room lighting and hotel bathroom lighting environments.

You’ll typically find these connectors used in areas like:

• Wardrobe internal LED strips with door sensors

• Headboard backlighting for subtle ambient glow

• Mirror edge lighting for balanced reflection

• Ceiling coves and under-bed accents to enhance spatial depth

The result? Faster installation, safer wiring, and a more consistent finish — all contributing to smoother handovers and lower long-term maintenance costs.

Choosing the right hotel LED lighting supplier isn’t just about finding the lowest quote — it’s about long-term consistency, compliance, and coordination. Certifications like CE, UL, RoHS, and ISO 9001 prove that the products are ready for international export and meet safety and quality standards that inspectors actually check during brand audits.

Equally important is driver compatibility. A professional hotel lighting supplier understands how to bridge 12 V / 24 V DC low-voltage systems with 110 V / 220 V AC hotel infrastructure. That’s what prevents flicker, overheating, or voltage drops that shorten LED lifespan — all issues that lead to guest complaints and warranty headaches.

When you evaluate samples, pay attention to measurable metrics:

• ΔE ≤ 1.0 → color consistency between batches

• CRI ≥ 90 → accurate color rendering for interior finishes

• Voltage ± 2 V → stable driver output for long-term reliability

Beyond the specs, what often derails hotel and hospitality LED lighting supplier projects is a fragmented supply chain. When joinery and lighting come from different vendors, dimensions, wiring channels, or plug types rarely match.

Betherev avoids that chaos through unified production — furniture, custom hotel lighting, and electrical routing built under one roof. The result: one warranty, one QC pipeline, zero mismatch. It’s a system that saves developers weeks of troubleshooting and guarantees the seamless, polished lighting experience every 5-star hotel demands.

Custom Hotel LED Lighting — Design, Control & Integration

Custom hotel LED lighting isn’t just about brightness — it’s about ambience that adapts to time and mood. Dimmable and color-tunable LED strips let you create day- and night-time settings that feel effortless. Guests can wake up to soft, natural light and unwind under a warm glow — all from the same fixture.

Smart control systems like DALI, Bluetooth, or motion sensors make lighting intuitive. In wardrobes and bathrooms, motion sensors eliminate the need for switches, while DALI or Bluetooth gives designers fine-grained control over brightness and color balance throughout the room.

The real efficiency comes when hotel LED lighting is integrated during factory production — built right into bed frames, mirrors, or cabinets. This reduces on-site wiring, minimizes electrician costs, and guarantees a cleaner, safer installation.

Technical specs matter too: 3000 K warm white, CRI > 90, and flicker-free 12 V / 24 V drivers are the gold standard for 5-star hotel lighting comfort and compliance.

At one coastal resort, indirect cove custom hotel lighting was used to accent natural stone walls and wooden ceilings. The result? A relaxed, organic glow that elevated the materials while cutting energy use.

Pro tip for interior designers: define control zones early. When your MEP team has clear hotel lighting zones from the start, sign-off and commissioning go much faster — and you avoid late-stage wiring headaches.

Technical & Installation Standards Developers Should Enforce

When it comes to hotel LED lighting, small technical oversights can cause big headaches later. Developers should treat lighting specs with the same rigor as joinery drawings — enforcing clear installation standards from day one.

For hotel bathroom lighting, IP44 protection is the baseline to guard against moisture. Outdoor zones demand IP65 to ensure durability under rain and dust. These ratings determine whether your fixtures survive their warranty period.

Always use aluminum extrusion channels to manage heat, especially for LED strips above 10 W / m. Without proper dissipation, LEDs fade faster and lose consistency. Each hotel room lighting zone should have its own driver to prevent voltage drop and flicker, which can otherwise ruin that smooth, five-star ambience.

Another smart step: pre-wire and test all connections before lamination, and clearly mark voltage compliance (12 V / 24 V) on labels. That small habit avoids confusion on site. Finally, enforce a 1 000-hour burn-in test before shipment — only lights maintaining at least 90 % lumen output after that test should make it to your project. It’s how you ensure reliability long after guests check in.

Case Studies — How Developers Achieved Faster Handover

Real-world projects show how much time and coordination can be saved when hotel LED lighting is integrated directly into furniture during production.

Mercure Flagstaff Melbourne is a great example. By using 24-volt mirror LEDs pre-wired at the factory, electricians only had to plug in the fixtures on site. That single change cut installation time by almost 80 %, helping the developer finish guest rooms weeks ahead of schedule.

At the One Hotel in Costa Rica, Betherev built LED strips directly into the wardrobes and vanities. The lights were already wired, tested, and fitted with Dupont plug connectors before shipping, which meant no on-site soldering or rewiring was needed.

Both projects used Betherev’s Dupont-connector system and digital QC tracking, ensuring every lighting point matched the approved drawings. Developers reported cleaner wiring, fewer inspection issues, and smoother MEP coordination — all contributing to a noticeably faster handover.

Hidden ROI — Lighting as a Financial Strategy

Lighting isn’t just about how a room feels — it’s a quiet line item that shapes long-term profit. When hotels switch to low-voltage integrated hotel LED lighting systems, they typically see 20–30 % reductions in operating energy costs within the first five years. That’s real OPEX savings that compound across hundreds of rooms and thousands of fixtures.

Beyond energy, there’s maintenance. Fewer failures mean fewer technician call-backs, less re-mobilization, and no weekend “urgent” rewiring costs. Stable, flicker-free systems also prevent brand audit deductions — especially when global operators like Hilton or Accor check for color consistency and CRI compliance.

Betherev’s Dupont-connector hotel lighting system adds another hidden win. Plug-and-play joints shorten installation time and reduce post-handover defect-liability periods. And because the FF&E and hotel lighting ship together, you save on CBM, freight fees, and coordination overhead. In other words, smart hotel LED lighting isn’t an expense — it’s a financial strategy disguised as design.

Conclusion

A well-designed hotel LED lighting system isn’t just about creating atmosphere anymore — it’s about efficiency, safety, and long-term savings. When developers switch to low-voltage hotel LED lighting with smart controls and Dupont connectors, they turn what used to be a decorative detail into a real financial asset.

Every wire, connector, and hotel light strip adds up to smoother coordination, faster installation, and fewer maintenance calls down the line. Lighting becomes a contributor to ROI — not a cost center.

That’s where Betherev, an experienced hotel LED lighting supplier, makes the difference. With over 30 years in FF&E and custom hotel lighting manufacturing, the team delivers integrated solutions that meet 5-star hotel lighting standards, pass safety audits, and stay on schedule. Partnering with Betherev means you’re not just buying fixtures — you’re investing in reliability, compliance, and peace of mind for your entire project.

FAQs

Dupont connectors transform LED installation into a plug-and-play process. They eliminate on-site soldering or taping, reduce labor costs, and ensure uniform, safe connections across all guest rooms.

Low-voltage (12V / 24V) hotel LED lighting systems reduce the risk of electrical shock and overheating, making them ideal for enclosed joinery or moisture-prone areas like hotel bathrooms. They also comply with CE and UL international safety standards required by most hospitality operators.

Factory integration allows the LED strips, wiring, and connectors to be pre-installed in furniture such as wardrobes and mirrors. Once delivered on site, electricians only connect power. This process reduces installation time by up to 70%, saving weeks during fit-out.

Most hotel developers report 20–30% reductions in long-term operating energy costs, shorter installation times, and fewer maintenance issues — delivering both faster project turnover and better guest satisfaction scores.