Blog

2026 Built-In Hotel Joinery Guide

Table of Contents

You build hotels. Every millimeter matters.

In 2026, hotel joinery isn’t just cabinetry. It’s a critical path item that can make or break your handover timeline. Done right, it reduces rework, protects brand standards, and minimizes installation headaches.

Betherev is a custom joinery supplier specializing in built-in hotel joinery engineered to fit the first time—backed by CNC precision, factory mock-assembly, and site-sequenced packing. Whether you need wardrobes, vanities, headboards, minibars, bed frames, shelves, or even luggage racks for guest rooms, lobbies, or suites, this guide will help you evaluate joinery quality, avoid delays, and secure clean handovers.

Let’s dive into the materials, tolerances, quality checks, and project flows that matter most for any joinery inside your hotel.

1. What Is Built-In Hotel Joinery?

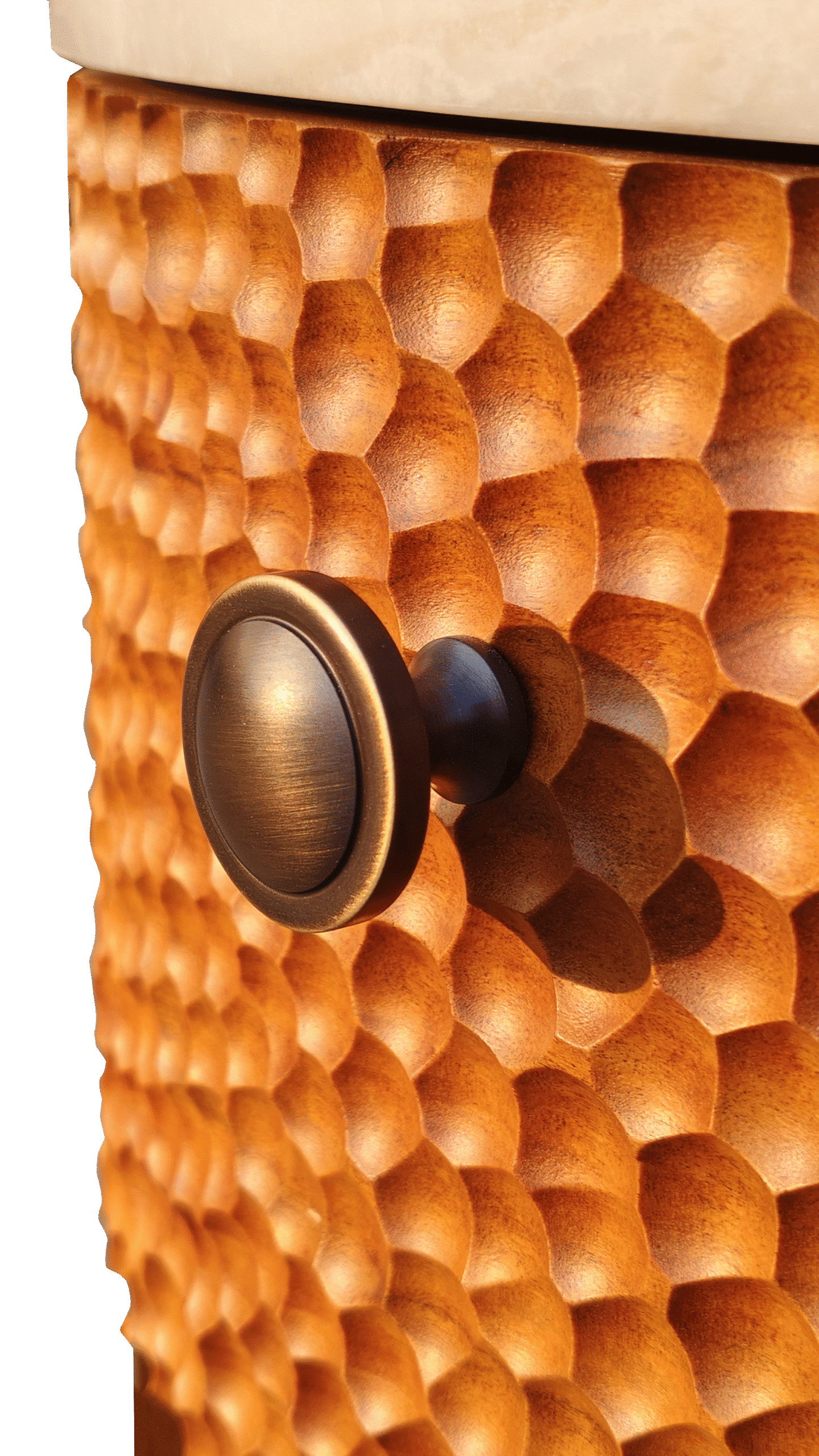

Betherev is not only a wood joinery manufacturer and supplier — we specialize in multi-material integration for modern hotel environments. Our joinery solutions combine:

- Wood (solid timber, plywood, MDF)

- Marble and artificial stone surfaces

- Metal accents and framing (brass, stainless steel, powder-coated steel)

- Rattan and woven panels for tropical or biophilic aesthetics

- Wallpapers applied to paneling and integrated wall systems

- Fabric and Leather Upholstery for padded headboards, wall panels, benches

- Artwork and decorative inlays built into joinery modules

We design and manufacture seamless, pre-fitted elements that elevate your hotel’s design vision — without compromising site speed, safety, or structural integrity.

Built-in hotel joinery includes custom, fixed furniture units like wardrobes, minibars, bed frames, headboards, TV walls, shelves, and luggage racks that integrate with architectural elements and MEP services.

Ideal Clients: – Hotel developers – General contractors – FF&E procurement teams – Interior designers

These components are manufactured to tight tolerances, installed permanently, and must coordinate with finishes, electrical, and plumbing layouts across the entire hotel—not just guest rooms, but also lobbies, corridors, and public spaces. Built-in hotel joinery includes custom, fixed furniture units like wardrobes, minibars, bed frames, headboard panels, TV walls, shelves, and luggage racks that integrate with architectural elements and MEP services.

Ideal Clients: – Hotel developers – General contractors – FF&E procurement teams – Interior designers

These components are manufactured to tight tolerances, installed permanently, and need to coordinate with finishes, electrical, and plumbing layouts across the entire hotel—not just guest rooms, but also lobbies, corridors, and public spaces.

2. Why Built-In Joinery Matters in 2026

- Compressed Schedules: Construction cycles are shorter; delays in joinery can delay entire projects.

- Higher Expectations: Brands now demand perfect alignment, consistent finishes, and high durability.

- Compliance & Audits: Fire-rated cores, VOC-safe finishes, and tight tolerances are not optional.

Get it wrong? You face rework, penalties, and consultant rejections.

Get it right? You install once. You hand over cleanly.

3. Key Components of Hospitality Joinery

Cores

- E0/E1 plywood

- Moisture-controlled 6–10%

Surfaces

- HPL for high-impact zones

- Veneer (natural or engineered) for premium look

- PU or water-based lacquer for repairable surfaces

Hardware

- European hinges/runners (Hettich, Blum)

- Pull strength and alignment guaranteed over thousands of cycles

Wet Zones

- Sealed edges

- Correct backings

- Moisture-resistant boards around vanities/minibars

Typical Joinery Items in Hotels

- Guest room wardrobes

- Built-in minibars

- Bed frames and headboards

- Open shelves and display units

- Wall-mounted luggage racks

- TV paneling

- Vanity cabinets and mirrors

All built-in joinery must meet performance, visual, and installation efficiency requirements.

Betherev transforms approved shop drawings into millimeter-perfect components.

- Tolerance: Cut to ±0.2 mm

- Traceability: Barcoded by room/floor

- Reality Proofing: Adjustable plinths, scribes for non-plumb walls

- Optimization: Nesting software reduces waste

Result: No rework. No surprises.

5. Edge Banding and Pre-Fit Details

- Edge Sealing: Auto lines for straight runs, handwork for curves

- Joinery Prep: Dados, rebates, and fixing grooves CNC-routed

- Color Matching: Verified under warm hotel lighting

- Drilling: Hinges, runners, connectors routed to ±0.1 mm

On-site assembly is fast, accurate, and quiet.

6. Veneer & Finish Standards in Hotels

Process

- Veneer hot-press at 90–120°C

- Sanding sequence: 180 → 240 → 320 grit

- Coatings: Eco PU or water-based

Performance Targets

- Film thickness: 30–50 µm

- Color tone: ΔE ≤ 1.0

- Scratch & stain resistance

It looks premium and holds up under heavy use in any zone of your hotel.

7. Mock Assembly & Quality Assurance

Mock-Ups

- Factory-assembled: headboard walls, wardrobes, vanities, luggage racks

Tests

- Drawer glides and soft-close

- Hinge alignments

- Plumbing and electrical clearances

- Hardware pull strength ≥ 80N

QC Process

- First-Article Check

- In-Process Batch Inspection

- Final 100% QC with photos and sign-off

Digital QC reports provided.

Quality Assurance Highlights

| Process | What we control | Standard |

|---|---|---|

| CNC cutting | Matches architectural layout | ±0.2 mm |

| Moisture | Prevent warping/swelling | 6–10% |

| Drilling & grooves | Fit & alignment | ±0.1 mm |

| Finishing | Tone & gloss consistency | ΔE ≤ 1.0 |

| Mock-assembly | Fit verified before shipping | ±1 mm |

| Packaging | Export-safe, site-ready | Drop/humidity tests passed |

8. Packing & Site Coordinatio

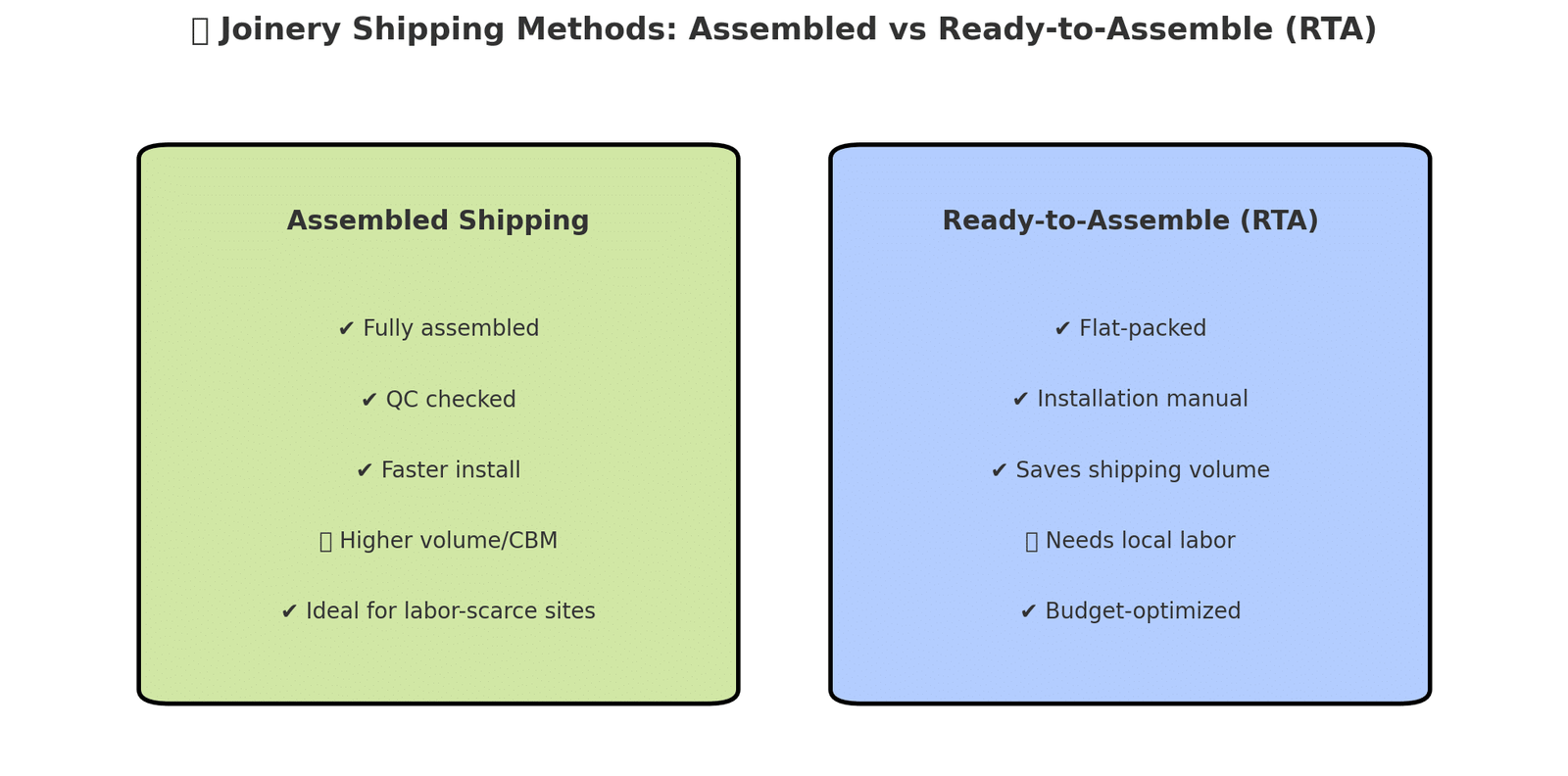

At Betherev, we offer two smart shipping methods — both designed to match your on-site conditions and workforce setup.

Option 1: Assembled Shipping

Units are fully assembled in our factory

Undergo full QC before shipping

Packed with foam, corner protectors, and support frames

Fastest installation on site

Best for sites with limited labor or tight timelines

Option 2: Ready-to-Assemble (RTA) Shipping

Joinery is flat-packed by module

Each piece is clearly labeled with hardware and manuals included

Reduces CBM, saving shipping costs

Ideal when skilled local installers are available

How We Pack Smarter

Site Sequencing

Packed by room and install order

Cartons clearly labeled: floor / room / install step

Protection Materials

EPE foam

Bubble wrap

Corner guards

Desiccants (for moisture control)

Shipping Terms

Support FOB, CIF, DDP

Containers are loaded in install order, not bulk

No reshuffling. No missing parts. No wasted labor.

9. Typical Project Timeline & Site Handover

Inputs Needed: – Approved shop drawings – Room matrix – Brand finish schedule – Site delivery plan

Phase | Timeline |

Shop drawings & samples | 2–3 weeks |

Production | 6–10 weeks (scope-dependent) |

Packing | 1 week |

Transit | 3–5 weeks (EU/ME average) |

We also recommend one Mock-Up Room (MUR) per typology.

- Skipping mock-ups

- Ignoring sealed edges in wet zones

- Missing electrical cut-outs

- Not labeling cartons by room

- Using non-compliant adhesives or coatings

- Forgetting scribe pieces for imperfect walls

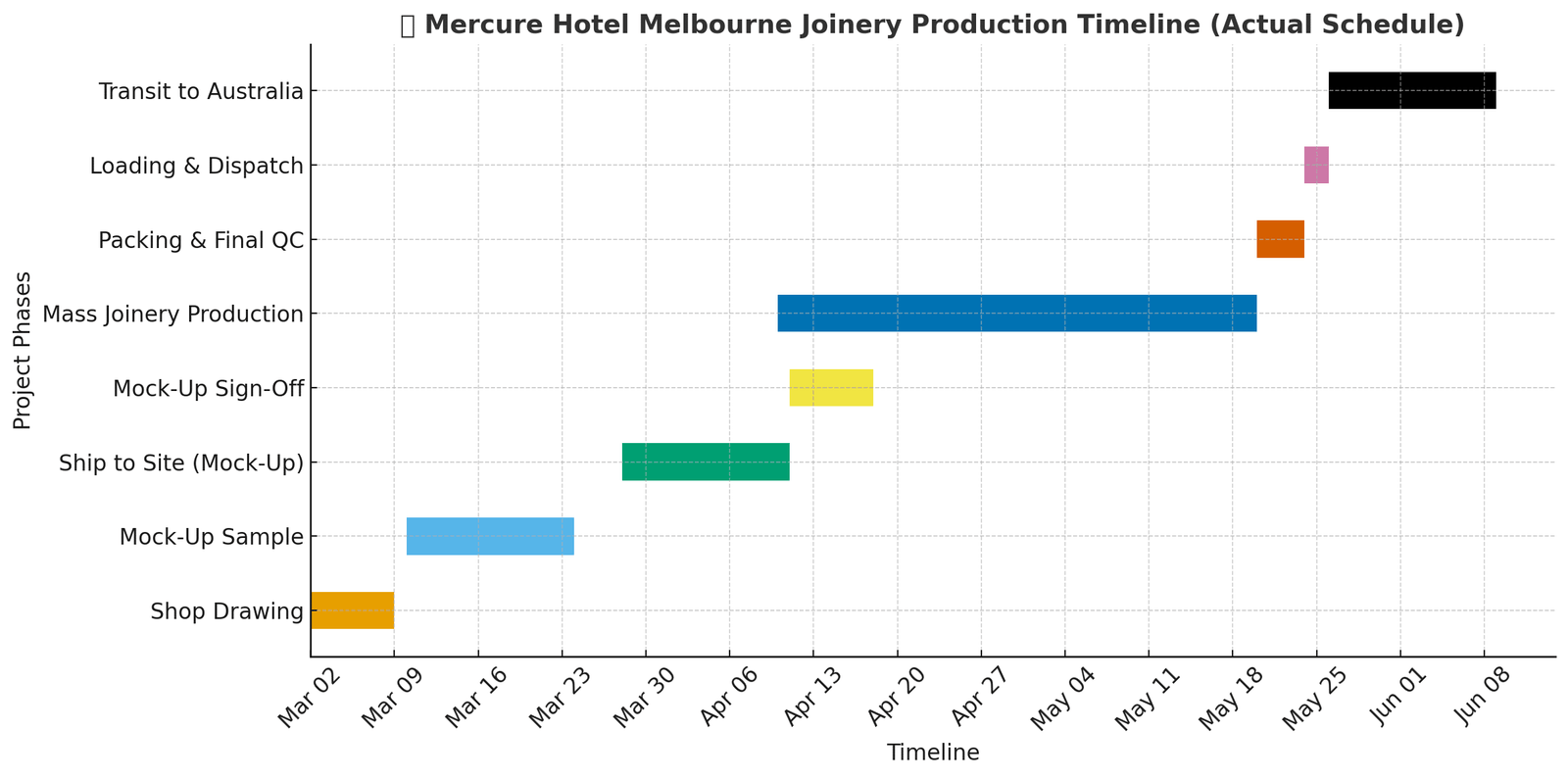

Project: Mercure Hotel, Melbourne

Scope: Full-scale built-in hotel joinery manufacturing for guest rooms and public areas

Production Time: 40 days

Total Joinery Units: 1,500+ components

Joinery Scope Delivered:

- Joinery Bed Frame: Integrated timber construction with upholstered panels and power/data access

- 3-in-1 Guest Room Unit: Combined wardrobe, minibar housing, and luggage rack — precision fit to room layout

- Vanity Cabinet: Moisture-resistant joinery with sealed edges and power/plumbing access pre-cut

- Twin Mirror Assembly: Wall-mounted mirror units matched for tone and gloss level (ΔE ≤ 1.0)

Performance Notes:

- Delivered on schedule in 40 production days

- Pre-assembled mock-up approved by developer and hotel brand team

- Packed by room and sequence for rapid on-site installation

- Full QC photo reports submitted at each phase

Phase | Duration | Dates |

Shop Drawing | 7 days | Mar 2 – Mar 9 |

Mock-Up Sample | 14 days | Mar 10 – Mar 24 |

Ship to Site (Mock-Up) | 14 days | Mar 28 – Apr 11 |

Mock-Up Sign-Off | 7 days | Apr 11 – Apr 18 |

Mass Joinery Production | 40 days | Apr 10 – May 20 |

Packing & Final QC | 4 days | May 20 – May 24 |

Loading & Dispatch | 2 days | May 24 – May 26 |

Transit to Australia | 14 days | May 26 – Jun 9 |

This project showcases Betherev’s ability to deliver precision joinery under tight timelines — integrating wardrobes, minibars, and luggage stations into unified modules that fit perfectly on site.

n hotel joinery, fit equals time saved. Betherev delivers engineered joinery with factory discipline so your site installs run smoothly, not slowly.

Want a quotation? Email your BOQ or drawings today. We’ll respond with: – Itemized pricing – Recommended materials – Packing and delivery plan

- Do they provide room-sequenced packing?

- Can they prove CNC precision and mock-ups?

- Do they supply digital QC reports?

- Can they meet VOC, fire, and durability compliance?

- Will they coordinate power, plumbing, and finishes?

Betherev does. Let’s build something remarkable together.

FAQs

CNC cutting from your shop drawings (±0.2 mm), barcodes by room, and factory mock-assembly. We verify power/plumbing clearances before shipping.

Yes. We review CSD, pre-cut openings for sockets, plumbing, and ventilation, and label routes. It prevents clashes and keeps your fit-out sequence moving.

Send drawings or BOQ. You’ll get a detailed, itemized joinery quotation with materials, lead time, and delivery plan.

We plan backward from your milestones, share weekly photo updates, and pack by room/sequence—so installation tracks with the construction program.