Blog

Hotel Fit Out with Custom Furniture & Joinery:

How to Build Spaces That Last

Table of Contents

Most hotel fit out problems don’t start on site.

They start with furniture and joinery decisions that look fine in drawings—but fail in real use.

Custom hotel furniture and joinery sit at the center of every successful hotel fit out. This article explains how bespoke furniture, built-in joinery, and smart manufacturing decisions directly impact cost, durability, timelines, and guest experience.

Why Custom Furniture & Joinery Define the Quality of a Hotel Fit Out

Most hotel furniture looks fine on day one. The real test in a hotel fit out starts after six months of guests, luggage, cleaning carts, and daily wear.

That’s where the difference between off-the-shelf furniture and custom hotel furniture becomes obvious. Off-the-shelf pieces are designed for homes or light commercial use. Custom hotel furniture is built for constant use, tighter tolerances, and long-term abuse—without falling apart or looking tired.

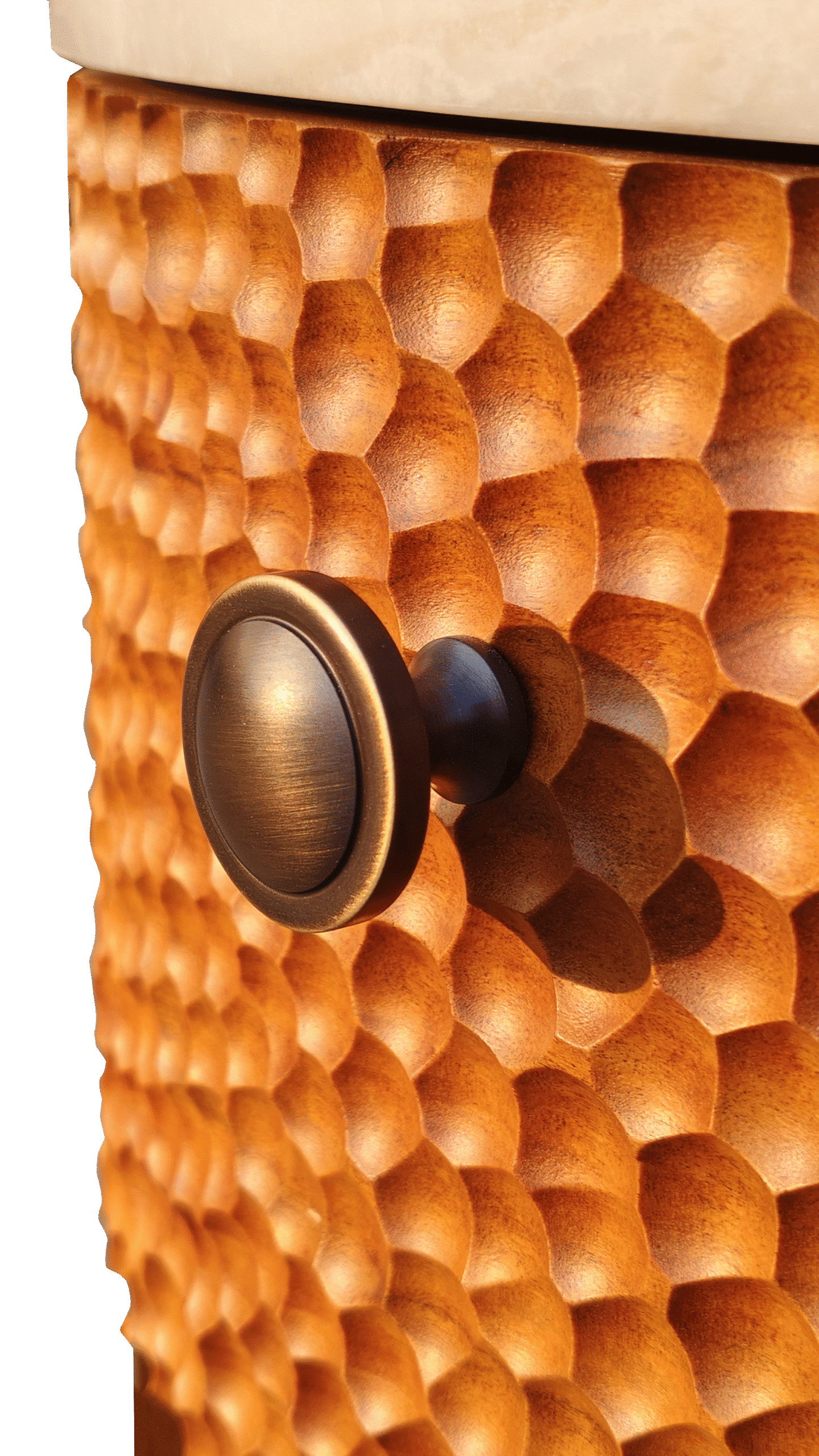

Joinery is the backbone of a hotel fit out. Wardrobes, vanities, TV panels, minibars, and built-ins don’t just hold things; they control how space is used. Good joinery maximizes storage, eliminates dead corners, and keeps rooms feeling larger even when square meters are limited.

Built-in furniture also changes how a hotel operates every day. Housekeeping moves faster when edges are sealed, kick plates are protected, and furniture doesn’t shift. Maintenance teams spend less time tightening screws or replacing broken panels because the structure was designed for hotel life from the start.

There’s also a constant tension between brand standards and operational reality during a hotel fit out. Design guidelines look great on paper, but they don’t always account for local climate, cleaning methods, or guest behavior. Customization allows those standards to be respected—while quietly fixing the parts that would otherwise fail in real use.

Customization doesn’t always mean higher cost. In many hotel fit out projects, it actually saves money by reducing material waste, simplifying components, and avoiding expensive retrofits later. When furniture is designed specifically for the room, the hotel pays once instead of paying again in repairs, replacements, and downtime.

What Custom Hotel Furniture & Joinery Include in a Fit Out Scope

Not all hotel furnishing suppliers serve the same function, even if their marketing looks similar. Choosing the wrong type for a project can increase risk, cost, and coordination effort.

When people hear “custom hotel furniture,” they usually think about what goes into the guestroom of a hotel fit out. And yes—that’s a big part of it. Beds, wardrobes, minibars, vanities, desks, bedside tables. These pieces are designed to fit the room layout exactly, meet brand standards, and survive years of heavy use, not just look good on opening day.

But a real hotel fit out goes beyond loose furniture. Fixed joinery is where many projects succeed—or struggle. This includes TV panels, headboards, wall cladding, integrated shelving, and full storage walls. These elements are built into the room, tied to electrical and lighting layouts, and usually installed before the loose furniture even arrives.

Public areas add another layer of complexity in a hotel fit out. Reception desks, bar counters, restaurant banquettes, buffet joinery, and lounge feature walls all fall under custom joinery. These pieces deal with higher traffic, stricter fire and safety requirements, and constant wear. They also set the first impression of the hotel, so mistakes here are very visible.

Then there’s back-of-house, which is often forgotten until it becomes a problem. Staff pantries, service counters, linen storage, housekeeping cabinets, and office joinery may not be guest-facing, but they directly affect operations within the hotel fit out. Poor BOH joinery slows staff down and creates daily frustration that never shows up in the renderings.

This is where scope definition really matters. When furniture and joinery packages are incomplete or loosely defined during a hotel fit out, gaps appear—missing panels, unclear responsibilities, late design changes. That leads to rework, delays, rushed site fixes, and cost overruns. A clear, detailed fit out scope upfront saves time, money, and a lot of uncomfortable emails later.

Hotel Fit Out Process When Custom Furniture Is Involved

When custom furniture is part of a hotel fit out, the process has more steps—but each one exists for a reason. Skipping or rushing any of them usually shows up later as delays, rework, or cost overruns. Understanding how these stages connect helps you keep control of the hotel fit out instead of reacting to problems.

Design development and shop drawings are not the same thing.

Design drawings show intent—layout, look, and overall concept. Shop drawings translate that intent into buildable instructions with exact dimensions, materials, fixing methods, and tolerances. A hotel fit out can look perfect on paper and still fail if the shop drawings aren’t detailed enough to manufacture and install correctly.

Mock-up rooms are where theory meets reality.

Before mass production, one or more prototype rooms are built using the exact furniture, joinery, finishes, and lighting specified for the hotel fit out. This step confirms proportions, comfort, durability, and how everything works together in real space.

Material samples matter more than most people expect.

Wood veneer, laminate, fabric, stone, metal finishes, and hardware all behave differently under lighting, humidity, and daily use. Reviewing physical samples avoids surprises later in the hotel fit out—especially when similar-looking finishes perform very differently over time.

Production isn’t one big batch—it’s sequenced.

Joinery, loose furniture, upholstery, and metal components often move through different workshops and timelines. Smart sequencing ensures items needed first on site are produced and shipped first, reducing storage issues and installation clashes during the hotel fit out.

Finally, coordination is what keeps everything moving.

Factories, freight forwarders, installers, and site teams must work from the same timeline and drawings. When communication breaks down, furniture arrives too early, too late, or in the wrong order—derailing the hotel fit out schedule.

Cost Control in Hotel Fit Outs Using Custom Furniture & Joinery

Custom furniture pricing in a hotel fit out isn’t a mystery, but it is layered. Most of the cost comes from three places: materials, labor, and volume. Better materials and more complex construction raise costs fast, while higher quantities usually bring unit prices down. This is why early decisions matter more than last-minute negotiations.

Veneer, laminate, and solid wood can look similar—but their costs and performance are very different within a hotel fit out. Laminate is usually the cheapest and most consistent, but it can feel flat in high-end spaces. Veneer offers a good balance of cost, warmth, and repairability, while solid wood looks premium but increases material waste, labor time, and long-term movement risk.

One of the easiest ways to control hotel fit out cost is smart standardization. When wardrobes, vanities, or headboards share the same internal structure across room types, factories can reuse drawings, jigs, and materials.

Good joinery engineering saves money quietly in a hotel fit out. Thinner panels where loads are low, shared backing boards, modular carcasses, and simplified fixing details all reduce material and labor without changing how the room looks.

The lowest quote in a hotel fit out usually cuts corners you don’t see until the hotel opens. Weak substrates, poor hardware, and rushed finishes lead to repairs, replacements, and downtime. Paying slightly more upfront for durable joinery often costs less over the life of the hotel.

Choosing the Right Custom Furniture & Joinery Partner

Not all “suppliers” play the same role in a hotel fit out. Some are factory-direct manufacturers. Others are trading companies that outsource production. That difference matters when timelines get tight or details need to change.

In-house joinery capability is a big deal for any hotel fit out. When wardrobes, vanities, wall panels, and casegoods are produced under one roof, coordination is tighter and mistakes are easier to fix.

Always verify real hotel project references relevant to your hotel fit out. Ask for projects similar in size, brand level, and scope—not just a few nice photos.

Pay attention to red flags early in the hotel fit out process:

-

Drawings that stay vague

-

Lead times that sound too good to be true

-

Material specs without clear standards

Common Hotel Fit Out Failures Linked to Poor Furniture & Joinery Decisions

A lot of hotel fit outs don’t fail all at once.

They fail quietly—drawer by drawer, hinge by hinge, panel by panel.

Using MDF where plywood or solid core is required is one of the most common hotel fit out mistakes. Climate, hardware shortcuts, transport damage, and unclear warranties all compound into long-term problems that are expensive to fix after opening.

Most hotel furniture failures are predictable.

They only feel “unexpected” when hotel fit out decisions were rushed early on.

When a Long-Term Custom Furniture Strategy Makes Sense

For multi-property developers, a hotel fit out becomes a repeatable system. Retained drawings, approved joinery details, and proven furniture designs reduce risk, speed up delivery, and keep quality consistent across projects.

The biggest benefit shows up quietly over time.

Fewer defects. Fewer surprises. Fewer emergency fixes during the hotel fit out lifecycle.

Conclusion

A hotel fit out is only as strong as its furniture and joinery.

When custom hotel furniture is designed, engineered, and manufactured correctly, it supports operations, protects budgets, and extends the life of the hotel fit out. When it’s treated as an afterthought, it becomes the source of most failures.

Next step: review your current hotel fit out plan and ask whether your furniture and joinery decisions are driven by drawings—or by real-world use.

FAQs

A hotel fit out typically includes custom hotel furniture, fixed joinery, lighting, finishes, and installation within guest rooms, public areas, and back-of-house spaces. This often covers wardrobes, vanities, headboards, TV panels, reception desks, and other built-in elements essential to daily hotel operations.

Custom furniture is designed specifically for hotel use, meaning it handles heavy daily wear, housekeeping cycles, and guest behavior better than off-the-shelf products. In a hotel fit out, custom furniture improves durability, space efficiency, and long-term cost control.

Hotel fit out furniture is engineered for commercial use, with stronger internal structures, higher-grade materials, and heavy-duty hardware. Residential furniture may look similar but is not designed for constant use, frequent cleaning, or long-term durability in a hotel environment.

Hotel fit out costs vary depending on hotel size, brand level, materials, and scope. Custom furniture and joinery usually represent a significant portion of the budget, but smart design, standardization, and proper engineering can reduce lifecycle costs and avoid expensive replacements later.

Custom furniture and joinery should be finalized early in the hotel fit out process, ideally during design development. Early decisions allow accurate shop drawings, mock-ups, and production planning, reducing delays and last-minute changes during installation.

Common hotel fit out mistakes include using MDF in high-moisture areas, ignoring climate conditions, choosing weak hardware, skipping mock-up rooms, and unclear warranty responsibilities. These issues often lead to early failures after opening.

A hotel fit out involving custom furniture typically takes several months, including design coordination, shop drawings, mock-ups, production, shipping, and installation. Timelines depend on project size, complexity, and how early decisions are finalized.

Not always. While unit costs may be higher, custom furniture in a hotel fit out often reduces long-term expenses by improving durability, minimizing maintenance, and avoiding early replacement. In many cases, it lowers total lifecycle cost.

Responsibility depends on contract structure, but ideally the custom furniture and joinery manufacturer should be accountable for structure, materials, finishes, and workmanship. Clear warranty terms are essential to avoid disputes after installation.

Yes. For developers with multiple properties, retaining approved furniture and joinery designs allows future hotel fit outs to move faster, maintain consistent quality, and reduce design and approval time.