Blog

How to Ensure Brand Standard Compliance in Hotel FF&E Projects

Table of Contents

Brand standard compliance has become one of the most critical—and often misunderstood—components of modern hotel FF&E projects. Whether a property is operating under Hilton, Marriott, Accor, IHG, Hyatt, or Wyndham, each brand has specific requirements for furniture durability, finishes, lighting ambiance, upholstery performance, joinery construction, and guestroom ergonomics.

When these standards are not met during the brand audit phase, the consequences are immediate:

Failed inspections

Forced redesigns and rework

Cost increases and shipment delays

Postponed opening dates and lost revenue

Potential escalation with the brand’s technical review team

For developers, owners, and project managers, brand compliance is not just aesthetic — it directly affects ROI, schedule, and operational handover.

However, brand compliance is not guesswork. It follows a clear, repeatable workflow that begins long before the first piece of furniture is produced. When executed correctly, it makes brand audit approval predictable instead of stressful.

Let’s break down the workflow step-by-step.

1. Study the Brand Standards Before Design Begins

Understanding the brand standards at a documentation level is the foundation of compliance. Every major hotel group maintains:

FF&E design guidelines

Approved finish schedules

Ergonomic and safety standards

Lighting temperature and CRI requirements

Upholstery durability criteria (e.g., Martindale rub count)

Sustainability certifications (e.g., E0 plywood, FSC timber)

Our engineering and design team reviews all brand manuals before shop drawings begin.

This prevents misalignment later and ensures that design intent = brand-approved intent.

Why this step matters:

Starting with the right standards avoids costly “fixes” downstream.

Transition:

But brand compliance is not demonstrated in drawings—it is proven in real space.

2. Produce a Full-Scale Mock-Up Room

The Question:

Can you reduce housekeeping and maintenance budgets without sacrificing brand standards?

Common Industry Solution:

Developers often choose “scratch-proof” laminates and off-the-shelf light fixtures. Within a year, coatings dull and lights yellow, demanding constant polishing and bulb changes.

Betherev’s ROI-Driven Solution:

We use high-pressure laminates (HPL) with anti-fingerprint nano-coatings and 24 V LED systems with Dupont connectors for quick swap-outs.

This combination reduces maintenance labor by 40 % and replacement parts cost by 25 % annually.

In Waldorf Astoria Costa Rica, integrated casegoods + back-lit mirrors cut total OpEx by USD 38 000 per year across 250 rooms.

How to Align Design Vision and Production Practicality

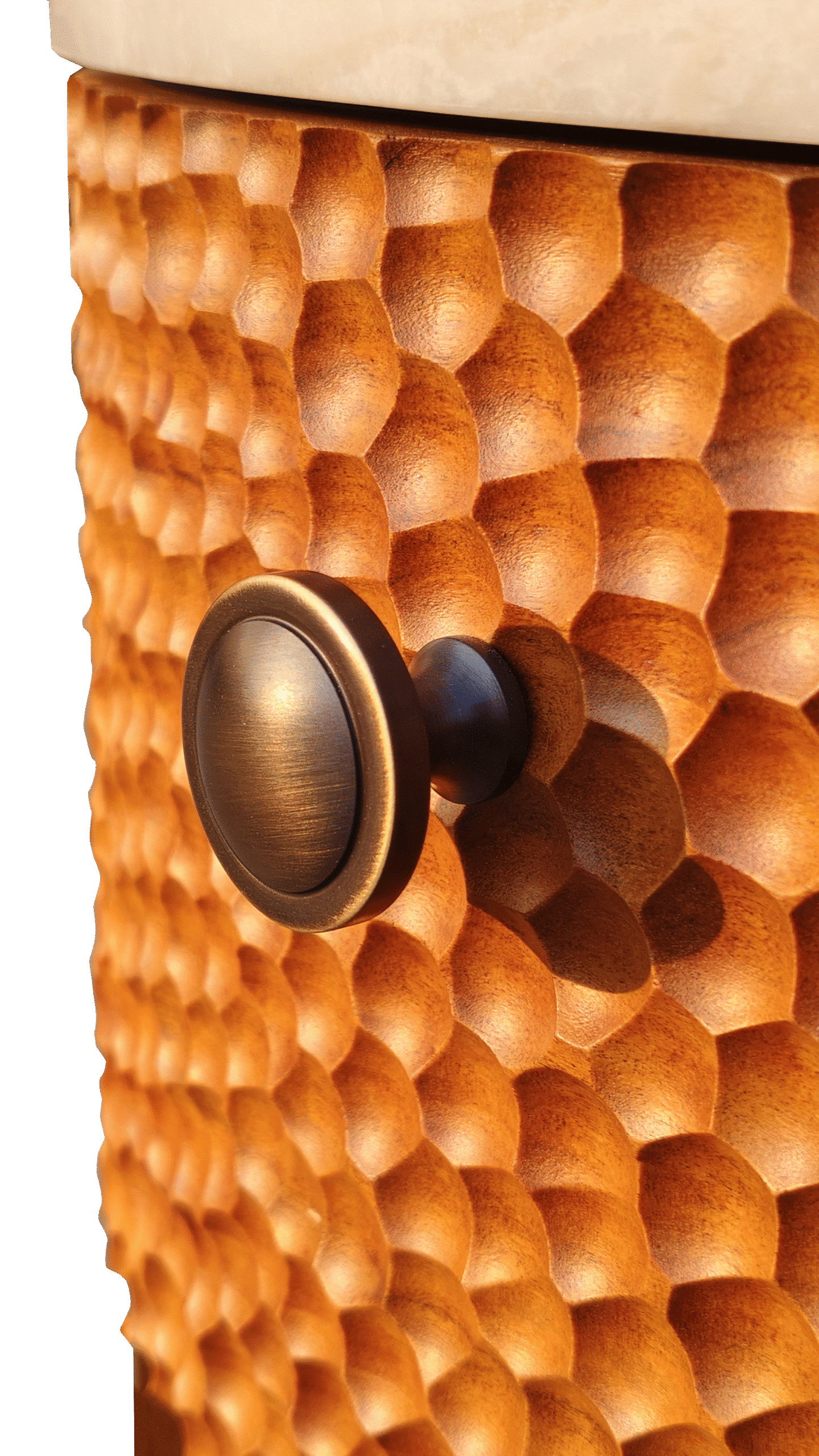

The mock-up room is where the design, finishes, and functionality are evaluated in a real, full-scale environment. A mock-up is not just about furniture placement — it is a performance review of the guest experience.

During mock-up evaluation, we test:

Veneer tone and grain direction

Edge radius and corner safety

Upholstery comfort and firmness

Drawer/door closing pressure & hardware performance

Lighting warmth (typically 2700K–3000K)

Acoustic comfort & reverberation behavior

Feedback is recorded directly with designers, owners, and brand auditors.

Why this step matters:

Correcting issues in the mock-up stage is fast and low-cost. Correcting issues after mass production is slow and expensive.

Transition:

However, even a perfect mock-up can lead to inconsistent final rooms if approvals are not documented correctly. That’s why the next step is critical.

3. Use a Digital Approval Workflow for Materials & Finishes

We use a centralized digital approval system to track:

Veneer boards

Fabric swatches

Hardware finishes

Metal powder coating

Stone or sintered tops

Lighting CCT/CRI specifications

Each approved material is photographed under controlled color conditions, uploaded to a project portal, and assigned a version-controlled approval record.

This means:

No miscommunication

No conflicting reference samples

No “but I thought we approved this tone” arguments

Why this step matters:

Documented approvals eliminate ambiguity and make brand auditors feel confident in vendor control.

Transition:

With approvals recorded, the next challenge is maintaining compliance across scale production, not just one mock-up room.

4. Conduct 30% / 60% / 90% QC Checks During Production

Brand compliance must be preserved during manufacturing, not inspected after the fact.

Our QC workflow includes:

| Stage | What We Verify | Purpose |

|---|---|---|

| 30% | Materials & joinery structure | Ensures durability and long-life performance |

| 60% | Upholstery tension, finish tone, veneer alignment | Prevents visual inconsistencies in mass production |

| 90% | Gloss value, edge radius, fabric tolerance, lighting performance | Ensures readiness for brand audit |

Technical tolerances we maintain:

Veneer color match ΔE ≤ 1.0

Dimensional tolerance ±0.5 mm

1000-hour LED driver burn-in test

CRIB 5 / CAL 117 fire performance where required

Why this step matters:

Consistency in final rooms is where brand trust is earned or lost.

Transition:

Finally, proof of reliability is demonstrated through real-world results.

Challenge: 6-year-old furniture fading; lighting color inconsistency hurting guest ratings.

Common Response: Replace furniture and lighting separately — double CapEx.

Betherev’s Strategy: Replace marble tops with sintered stone, refit spaces with matched 3000 K LED strips.

Result:

18 % CapEx savings

4-year extension of refurbishment cycle

Zero room downtime during warranty

+26 % total ROI improvement over 10 years

Conclusion

For developers, durability and integration equal profit.

By aligning furniture materials and lighting technology within one manufacturing ecosystem, Betherev turns FF&E from a cost line into a capital growth tool.

You protect ROI through reduced downtime, predictable maintenance budgets, and consistent brand presentation that guests — and investors — trust.

Next Step: Request a Hotel ROI Consultation

Brand standard compliance is not achieved at the end of the project — it is engineered from the start through:

Documented design interpretation

Real-space mock-up evaluation

Digital sample control

Structured production QC

Proven installation sequencing

When managed properly, the brand audit becomes a final verification, not a risk.

If your hotel project is currently in concept, sampling, mock-up, or pre-production, we can review your FF&E package and help identify compliance risks before they become delays.

→ Request a brand compliance review

FAQs

Most rejections occur due to mismatched finishes, inconsistent veneer tone, incorrect lighting color temperature, or failure to follow brand joinery standards.

It allows brand auditors, designers, and owners to evaluate finishes, comfort, ergonomics, and lighting before mass production begins.

They centralize sample decisions, prevent miscommunication, and ensure the approved finish is the one manufactured at scale.

Standard checkpoints include 30% joinery structure, 60% finish alignment, and 90% final inspection before packing and shipping.