Blog

Hilton Furniture Suppliers: How Betherev Helps Developers Build 5-Star Hotels

Table of Contents

When Hilton opens a new property, every detail — from the headboard finish to the lobby sofa stitching — follows a globally standardized Hilton furniture manufacturing process built for consistency, durability, and ROI.

For hotel developers, project managers, and interior designers, understanding the Hilton FF&E standards offers a shortcut to achieving five-star results: optimized sourcing, cost control, and repeatable quality.

At Betherev Hotel Furniture Factory, a Hilton-grade custom hotel furniture manufacturer, we’ve spent over 30 years producing FF&E, joinery, and loose furniture for international hotel brands. Here’s how we decode Hilton’s procurement logic — and how we apply it to your projects.

Hilton’s Furniture Procurement Model Explained

Hilton’s procurement system goes far beyond aesthetics — it’s an engineered compliance framework. Each Hilton approved vendor adheres to precise joinery depth, veneer matching, and upholstery fire-test ratings (CRIB 5 in the UK, CAL TB117 in the US).

This standardization ensures developers face predictable lead times and easier coordination with MEP and lighting schedules.

Equivalent-grade suppliers such as Betherev, located in Guangdong, can substitute approved vendors when they provide certified test results, sample boards, and mock-up room approvals matching Hilton’s specifications — often reducing logistics time by 4–6 weeks while maintaining brand compliance.

Hilton’s tiered supplier model (Tier 1 flagship / Tier 2–3 regional) shows developers how to balance cost and quality.

Example: DoubleTree by Hilton Dubai – Business Bay partnered with an integrated FF&E vendor similar to Betherev’s system, cutting procurement lead time and coordination errors dramatically.

✅ Key Takeaway: A supplier integrating joinery, lighting, and loose furniture shortens the project’s critical path — the true measure of Hilton-grade efficiency.

What Developers Can Learn from Hilton’s Supplier Selection Process

Hilton’s supplier approvals protect ROI. Factories must maintain ISO 9001 / 14001 certification, FSC timber, and E0 formaldehyde plywood — ensuring your fit-out passes local fire and building codes smoothly.

Betherev applies the same discipline:

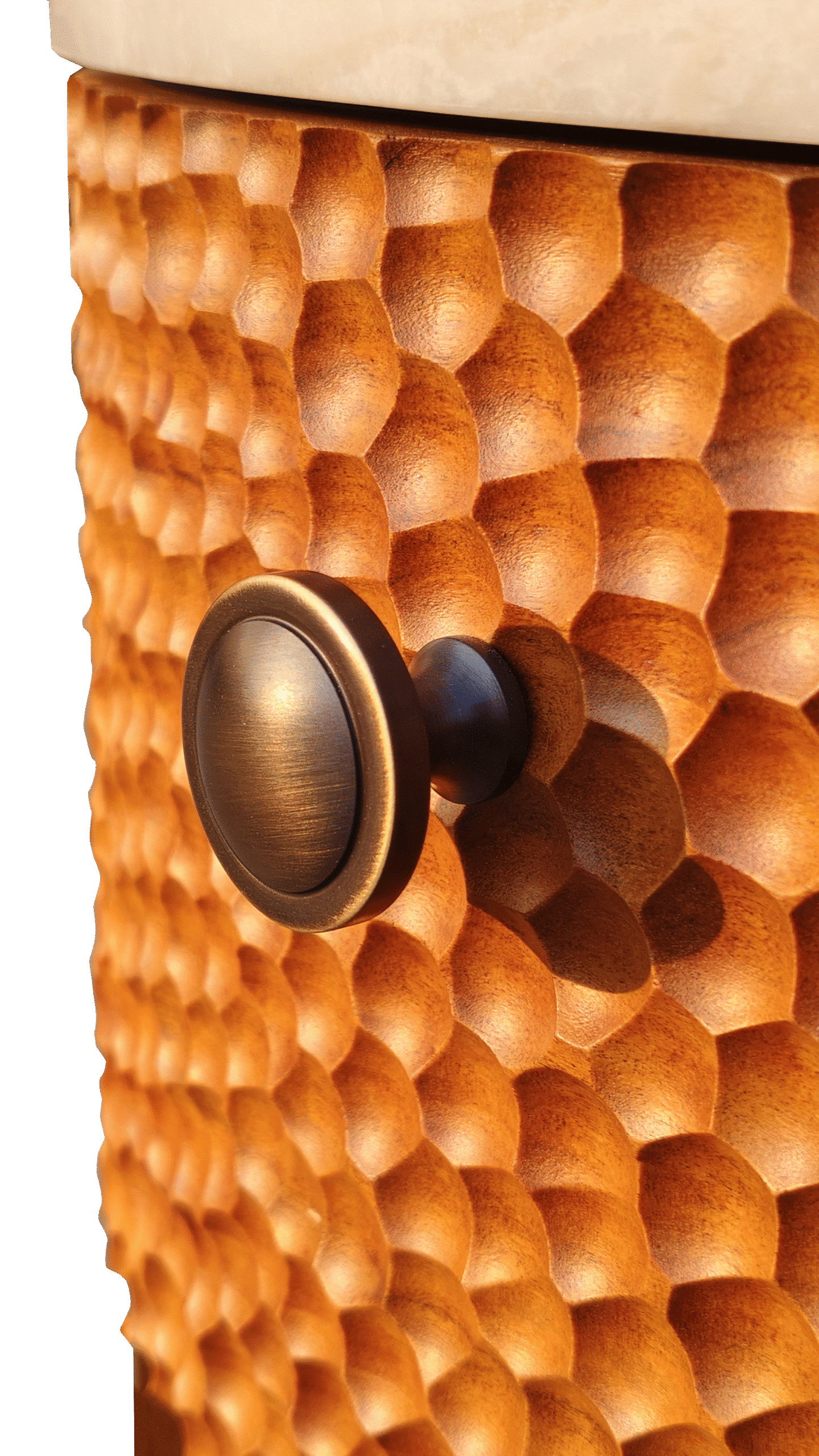

Unified production for joinery, veneer, and upholstery under one roof (prevents color mismatch and finish variance).

Color tolerance ΔE ≤ 1.0 and joinery tolerance ± 0.5 mm for precise fit-out.

Foam density ≥ 35 kg/m³ for high-traffic lobby and restaurant furniture.

Pre-shipment digital QC reports, drop-test results, and video documentation aligned with Hilton’s inspection templates.

💡 Pro Tip: Betherev’s weekly photo logs and humidity reports give designers real-time control over veneer tone and grain direction — preventing costly “wrong finish” delays on site.

Turnkey FF&E — Hilton’s Efficiency Secret, Betherev’s Core Strength

Hilton’s turnkey furniture supplier approach reduces risk and saves time because every discipline flows through one workflow.

Betherev mirrors this model, integrating:

Advantages for Developers & Project Managers:

Single purchase order for FF&E and lighting = simplified payment and warranty.

Unified QC system (ΔE ≤ 1.0 / ± 0.5 mm).

Room-based packing and barcode tracking for fast installation.

Phase-planned container loading to reduce on-site congestion.

Case Example: Hotel Santiago, Curio Collection by Hilton (Dominica)

By centralizing production with Betherev, the developer achieved:

40 % shorter fit-out timeline

20 % lower logistics cost

Zero delay penalties at handover

Each Betherev shipment includes shop drawings, mock-up reports, QC records, and digital installation manuals — fully traceable from factory to site.

Hilton sources FF&E from four core bases: China (Shunde), Vietnam, Turkey, and Eastern Europe.

Shunde’s ecosystem offers complete vertical supply chains — hardware, foam, marble, and metalwork within a 2-hour radius.

Betherev’s 50,000 sqm Foshan factory lies within this Hilton manufacturing hub, ensuring short lead times (55–60 days for full fit-outs) and tight QC loops.

For designers pursuing LEED certification, Betherev uses E0 plywood, water-based lacquer, and flame-retardant foam certified to CRIB 5 / CAL TB117 — earning up to 6 LEED credits for Hilton-aligned projects.

Flexible Shipping Options:

FOB — ideal for multi-country developer logistics.

CIF — predictable landed cost for contractors.

DDP — best for remote projects like Hilton Dominica Resort, avoiding customs delays.

Betherev’s DDP program includes room-labeled packaging, drop-test certification, and humidity-proof wrapping — directly inspired by Hilton’s sustainability protocols.

How Developers & Designers Can Achieve Hilton-Level Results with Betherev

Delivering Hilton-grade results requires structured process control.

Betherev’s five-step workflow follows Hilton’s FF&E procurement logic to keep projects on schedule and on spec.

Step 1 – Share Your Concept or FF&E Schedule

Betherev audits materials against Hilton standards (E0 plywood, CRIB 5 foam, 3M Scotchgard fabrics, LEED lacquer) and provides VE options to reduce weight and shipping cost.

Step 2 – Review Shop Drawings & Mock-Up Samples

Shop drawings integrate joinery + architectural interfaces.

Mock-ups confirm texture, comfort, and ergonomics for brand approval.

Step 3 – Begin Production with Digital QC Tracking

All production is in-house (CNC, veneer, painting, upholstery).

Each batch includes QR-coded QC sheets showing tolerances and foam density.

Weekly photo reports enable remote inspection by developers and consultants.

Step 4 – Room-by-Room Packaging & Shipment Sequencing

Furniture is packed per room/floor, barcode-labeled, and loaded by installation order — cutting site installation time by up to 25 %.

Step 5 – Installation Guides & After-Sales Support

Shipments include as-built drawings, hardware kits, maintenance files, and spare parts lists — aligned with Hilton operations manuals.

ROI Outcome: Hotel Santiago achieved 40 % faster fit-out and 28 % lower replacement costs within one year — proving Betherev’s Hilton-grade system delivers both quality and financial returns.

Conclusion

Hilton’s success is rooted in discipline and consistency — exactly what Betherev brings to every FF&E project.

For developers, designers, and project managers, partnering with Foshan Betherev Co., Ltd. means one accountable team for joinery, loose furniture, lighting, and fixtures — manufactured to Hilton standards and backed by digital traceability.

👉 Next Step: Contact Betherev Hotel Furniture Manufacturer to plan your next turnkey Hilton-grade project today.

FAQs

Hilton sources FF&E and furniture through an approved global vendor network — mainly in China (Guangdong/Shunde), Vietnam, Turkey, and Eastern Europe. These regions specialize in different product categories, such as joinery, upholstery, and metalwork.

Betherev, located in the same Shunde manufacturing hub, operates under Hilton-equivalent production standards and supplies custom joinery, loose furniture, and lighting to developers worldwide.

Betherev follows the same compliance matrix Hilton demands:

ISO 9001 / 14001 certified production

E0 plywood, FSC timber, CRIB 5 / CAL TB117 fire-rated foam

ΔE ≤ 1.0 color-matching precision and ± 0.5 mm joinery tolerance

These standards ensure Hilton-grade quality, durability, and sustainability across every guestroom and public area furniture piece.

Absolutely. Many non-branded or soft-branded hotel developers work with Betherev to achieve Hilton-level results without going through the official approval chain.

Betherev provides mock-up samples, QC documentation, and digital tracking identical to Hilton’s audit system — helping developers maintain 5-star standards while staying cost-efficient.

A turnkey FF&E partner like Betherev reduces risk and coordination time. Instead of juggling multiple subcontractors for joinery, upholstery, and lighting, developers issue one PO covering all FF&E.

This unified workflow shortens installation time by up to 40 % and prevents mismatched finishes — critical for on-time hotel openings.