Blog

Hotel Bedside Table (Nightstand) Design Guide:

What Actually Works in Guest Rooms

Table of Contents

Most hotel guests never compliment a bedside table—but they absolutely notice when it’s wrong.

Too small, no power socket, sharp corners, flimsy drawers. These details quietly affect comfort, reviews, and long-term maintenance costs. If you’re specifying a hotel bedside table (often called a hotel nightstand), this guide breaks down what actually works in real guest rooms—not showroom fantasy.

What a Hotel Bedside Table Needs to Do (Beyond Holding a Lamp)

A hotel bedside table does far more work than people realize. It’s not just a place to park a hotel bedside table lamp or room phone. It’s one of the most frequently used pieces of furniture in the guest room—touched daily, often half-asleep, and expected to function effortlessly.

First, it has to support real guest behavior. Phones, water bottles, glasses, books, eye masks—all end up there, sometimes at the same time. If the surface is too small or cluttered with decorative edges, guests feel it immediately. A good hotel nightstand provides enough flat space without forcing guests to stack items or worry about things tipping over.

Power access is non-negotiable. Modern guests charge everything. USB ports, Type-C, and universal sockets are now expected. What matters is integration. Cables shouldn’t hang awkwardly, ports shouldn’t face the wall, and power components must not interfere with drawer operation or stability.

Placement flexibility is another key requirement. In real hotel layouts, bedside tables are not always perfectly mirrored. Many rooms require the same unit to function comfortably on both the left and right side of the bed. That means drawer orientation, power access, and lamp placement must feel intuitive either way—without creating multiple SKUs.

Visually, the bedside table must carry its weight without stealing attention. It should relate clearly to the bed, headboard, and wall panels—matching materials, proportions, and detailing. Too light and it looks cheap. Too bulky and it competes with the bed. The best bedside tables sit quietly in the composition and make the room feel resolved.

Finally, it must meet hotel brand standards without being overdesigned. Hotel brands care about safety, durability, edge radii, finishes, and long-term maintenance. Unnecessary trims, fragile details, or decorative layers only create future problems—higher costs, more damage, and more replacements.

A good bedside table in hotel FF&E doesn’t draw attention to itself.

It just works—every night, in every room, for every guest.

Standard Hotel Bedside Table Dimensions (And Why They Matter)

Typical height range vs mattress + base height

In hotels, bedside table height typically falls between 500–650 mm (20–26 inches).

This range is designed to align with the combined height of the bed base, mattress, and topper. If the table is too low, guests must reach down awkwardly. If it’s too high, it blocks sightlines and feels intrusive next to the bed. The goal is simple: guests should be able to reach items without thinking.

Width and depth considerations for tight guestrooms

Guestrooms are tighter than they appear on drawings. Most hotel bedside tables stay within this practical range:

Width: 400–550 mm

Depth: 350–450 mm

This allows space for a lamp, phone, water bottle, and book—without eating into circulation space. Going deeper increases the risk of knee bumps and cramped layouts, especially in city hotels or adaptive-reuse projects.

Clearance for drawers, doors, and guest movement

A drawer that looks fine in CAD can fail in real life. Always allow for:

Drawer pull-out clearance (250–300 mm minimum)

Door swing if applicable

Nighttime walking paths around the bed

If a drawer opens into a guest’s leg path, it will be slammed shut—or broken. That’s why many hotels limit bedside storage to one shallow drawer or use open shelving to avoid clearance conflicts.

ADA / accessibility considerations in certain markets

In markets like the U.S., accessibility is regulated. For ADA-compliant rooms, bedside tables may require:

Reachable surface height from a seated position

Clear floor space for wheelchair access

Easy-to-operate hardware (no tiny knobs or stiff pulls)

Even if only a portion of rooms must comply, these requirements influence overall bedside table design.

Why residential sizing often fails in hotels

Residential bedside tables are designed for one person, in one home, with controlled habits. Hotels are different:

Guests vary widely in height and mobility

Furniture experiences heavier, faster wear

Housekeeping needs quick, unobstructed access

A residential nightstand may look good but often sits too low, is too deep, or uses fragile proportions. Hotel sizing prioritizes repeatable comfort at scale—and guests feel that difference, even if they can’t explain it.

Materials Used in Hotel Bedside Tables: Durability vs Cost

Choosing materials for a hotel bedside table is not just about appearance. It’s about how well the piece survives luggage impacts, cleaning chemicals, spills, and years of repeated use.

Price is paid once. Durability is paid for every day.

Veneer wood vs laminate vs solid wood in hospitality use

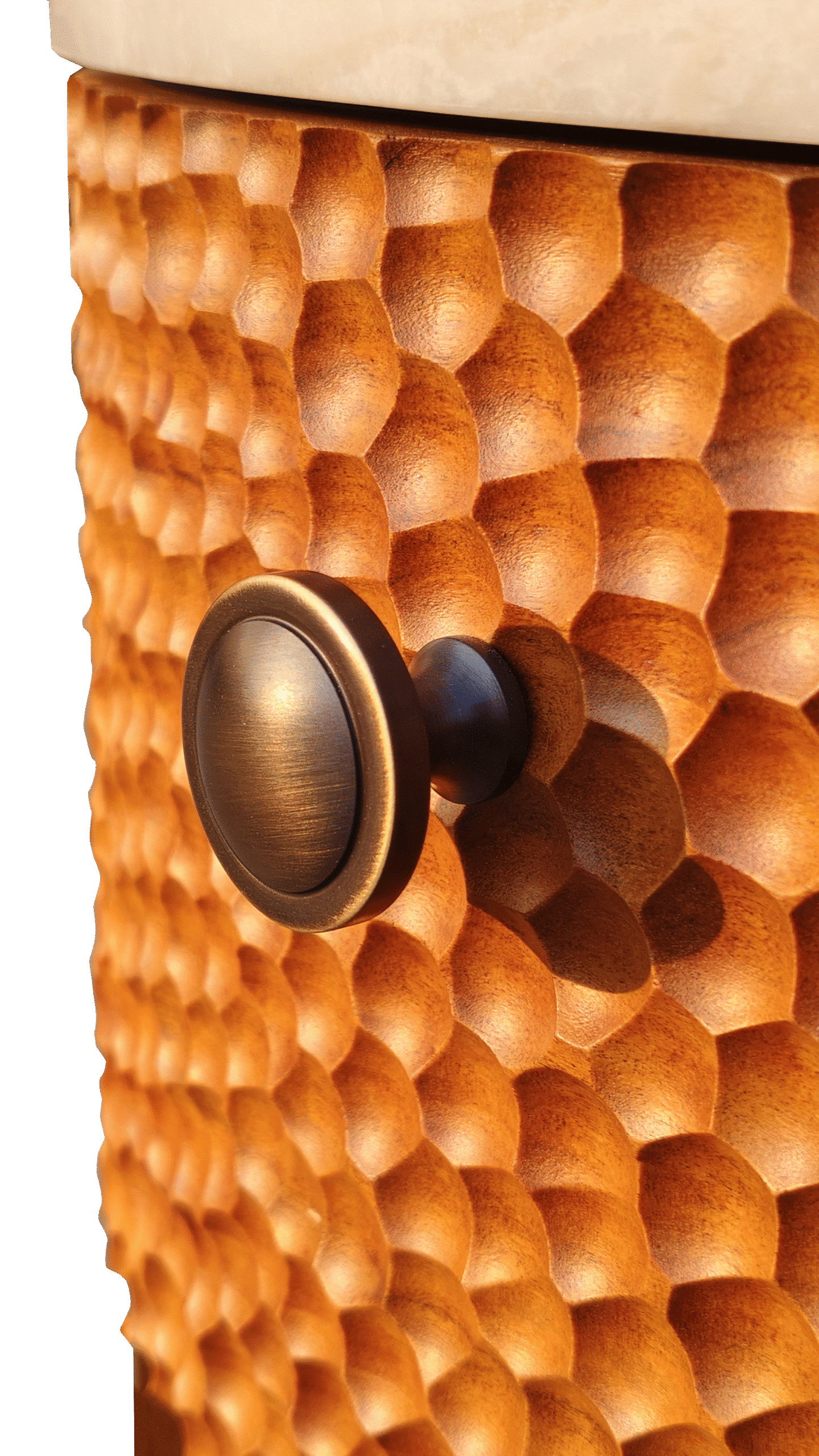

Veneer uses real wood bonded to a stable substrate and offers a premium look with better stability than solid wood. Laminate prioritizes durability and consistency, while solid wood requires careful engineering to avoid warping and cracking in hotel environments.

ubstrate choices: E0 plywood vs MDF

E0 plywood provides stronger screw holding and moisture resistance, while MDF delivers smooth surfaces but requires careful engineering to survive long-term use in hotel rooms.

Edge banding and corner protection in high-traffic rooms

Most bedside tables fail at edges and corners. Thicker edge banding, rounded corners, and proper sealing significantly extend furniture lifespan.

Hardware quality: runners, hinges, pull resistance

Drawer runners, hinges, and handles absorb daily abuse. High-quality hardware prevents noise, sagging, and repeated maintenance calls.

How material choice affects lifecycle cost

Hotels lose money through maintenance, not aesthetics. The best bedside table is the one that stays quiet, stable, and visually consistent over time—especially when sourced from an experienced hotel bedside table manufacturer or hotel bedside table supplier.

Power, Lighting & Functional Add-Ons Hotels Forget to Plan

Guests notice power and lighting issues immediately.

Built-in USB, Type-C, and international sockets are now standard expectations. Planning power integration at the bedside table design stage avoids messy extensions and exposed cables later.

Cable routing matters. Lamps, clocks, and chargers need proper channels to prevent pinching, noise, and wear. Poor routing shortens component life and creates safety risks.

When choosing between touch switches and physical switches, reliability usually wins. Touch switches look modern but can confuse guests at night. Physical switches remain intuitive—especially for nightstand lamp control.

Maintenance access is critical. Electricians should be able to replace power modules without dismantling furniture. Removable panels save hours of labor over the hotel’s life.

Fire safety and certification are non-negotiable. Integrated power systems must meet local electrical codes and brand standards. Cutting corners here always costs more later.

Common Hotel Bedside Table Mistakes (Seen After Installation)

Most problems don’t appear in drawings—they appear after guests check in.

Drawer collision with carpets or bed skirts

Veneer peeling due to poor edge sealing

Power modules placed too low or too far back

Sharp edges causing injuries or finish damage

Overdesigned tables that increase cost without improving function

Simple usually wins.

Custom vs Standard Hotel Bedside Tables — What to Choose

Standard bedside tables work when budgets and timelines are tight. They offer predictable pricing and faster delivery for straightforward layouts.

Custom bedside tables make sense when branding, integration, and layout matter. They align perfectly with headboards, wall panels, lighting, and power—creating a cohesive guest experience.

While custom units may cost more initially, batch production often reduces the gap. In many cases, custom even saves money by removing unnecessary decorative elements.

Mock-up rooms reveal reality. They expose clearance issues, power placement errors, and finish mismatches early—when fixes are cheap. A good hotel bedside table manufacturer helps optimize design before production, not after installation.

Conclusion

A hotel bedside table (nightstand) is a small item with outsized impact.

When specified correctly, it improves guest comfort, reduces maintenance issues, and quietly supports better reviews. Focus on function first, durability second, and aesthetics third—and you’ll end up with a bedside table that performs long after opening day.

If you’re planning a hotel project, treat the bedside table like infrastructure—not decoration.

When selected correctly, veneer helps project managers avoid defects, supports designers’ creative vision, and gives developers long-term value with fewer lifecycle costs.

If you’re planning a hotel or mixed-use development, choosing well-engineered hotel veneer wood furniture from a capable factory can save time, prevent redesigns, and elevate the entire project.

FAQs

Most hotel bedside tables are between 500–650 mm high, with widths of 400–550 mm and depths of 350–450 mm. The exact size depends on mattress height, room layout, and accessibility requirements.

For most hotels, E0 plywood with veneer or laminate finishes offers the best balance of durability and cost. Solid wood can be used but requires careful engineering, especially in humid environments.

Yes. Modern guests expect USB, Type-C, or universal power sockets at the bedside. These should be integrated into the bedside table design with proper cable routing and maintenance access.

E0 plywood for humid areas and E1 MDF for casegoods. These offer excellent stability and are widely used in globally approved hotel FF&E manufacturing.

Hotel bedside tables are designed for high-frequency use, durability, and ease of maintenance, while residential nightstands prioritize personal style. Hotel versions are usually stronger, more stable, and easier to clean.

Standard tables work for simple layouts and tight schedules. Custom hotel bedside tables are better when branding, power integration, and headboard coordination matter—especially in upscale or large-scale projects.